Waterproof Protection:

drysuit overboots. Some models include reinforced toes and heels, adding another layer of protection against impacts and protrusions that divers and kayakers may encounter.

drysuit overboots. Some models include reinforced toes and heels, adding another layer of protection against impacts and protrusions that divers and kayakers may encounter.

A Brief History

Another great thing about rain boots with tie is that they are versatile enough to be worn with a wide range of outfits

. Whether you're heading to work, running errands, or just enjoying a casual day out, these boots can easily be styled to complement any look. Pair them with jeans and a cozy sweater for a laid-back, chic ensemble, or dress them up with a skirt and blouse for a more polished and sophisticated vibe.

Grip studs wading boots are tailored for anglers and outdoor enthusiasts who require enhanced traction and stability in aquatic environments. These boots feature grip studs on the soles, providing superior grip on wet and slippery surfaces, such as riverbeds and rocks. The specialized design ensures secure footing while wading, making them an essential piece of gear for water-based activities.

They learn about the delicate balance of the ecosystem, the importance of every living creature, from the tallest tree to the smallest insect They learn about the delicate balance of the ecosystem, the importance of every living creature, from the tallest tree to the smallest insect

They learn about the delicate balance of the ecosystem, the importance of every living creature, from the tallest tree to the smallest insect They learn about the delicate balance of the ecosystem, the importance of every living creature, from the tallest tree to the smallest insect kids camo boots.

kids camo boots. This makes them suitable for professions that require frequent movement between hazardous and safer areas, such as machine operators, warehouse personnel, and even some healthcare workers who need to move swiftly from patient care to more physical tasks This makes them suitable for professions that require frequent movement between hazardous and safer areas, such as machine operators, warehouse personnel, and even some healthcare workers who need to move swiftly from patient care to more physical tasks

This makes them suitable for professions that require frequent movement between hazardous and safer areas, such as machine operators, warehouse personnel, and even some healthcare workers who need to move swiftly from patient care to more physical tasks This makes them suitable for professions that require frequent movement between hazardous and safer areas, such as machine operators, warehouse personnel, and even some healthcare workers who need to move swiftly from patient care to more physical tasks steel toe rubber slip ons.

steel toe rubber slip ons.When it comes to outdoor activities such as hunting and fishing, having the right footwear is crucial for comfort, protection, and performance. Camouflage insulated rubber boots are the ultimate choice for outdoor enthusiasts seeking the perfect blend of camouflage, insulation, and durability.

Waders serve as your first line of defense against the elements. They keep you dry, warm, and protected from the sometimes harsh conditions of fishing environments. However, for big and tall anglers, the standard options on the market are often limited, leading to discomfort or inadequate protection. Ensuring that you have the right size is crucial, as poorly fitting waders can hinder movement, cause chafing, and ultimately take away from the serene experience of fishing.

The insulated lining of these boots ensures that the wearer's feet remain warm and comfortable, even in the coldest of conditions. This is particularly important for those who work outdoors or in cold environments, as cold feet can not only be uncomfortable but can also lead to a loss of focus and increased risk of accidents.

Moreover, rubber boots are easy to clean and maintain, which is an attractive quality for many outdoor enthusiasts. After a day of muddy adventures, a simple rinse with water is usually all it takes to restore your boots to their original state. This ease of maintenance makes them a practical choice for anyone who frequently engages in outdoor activities.

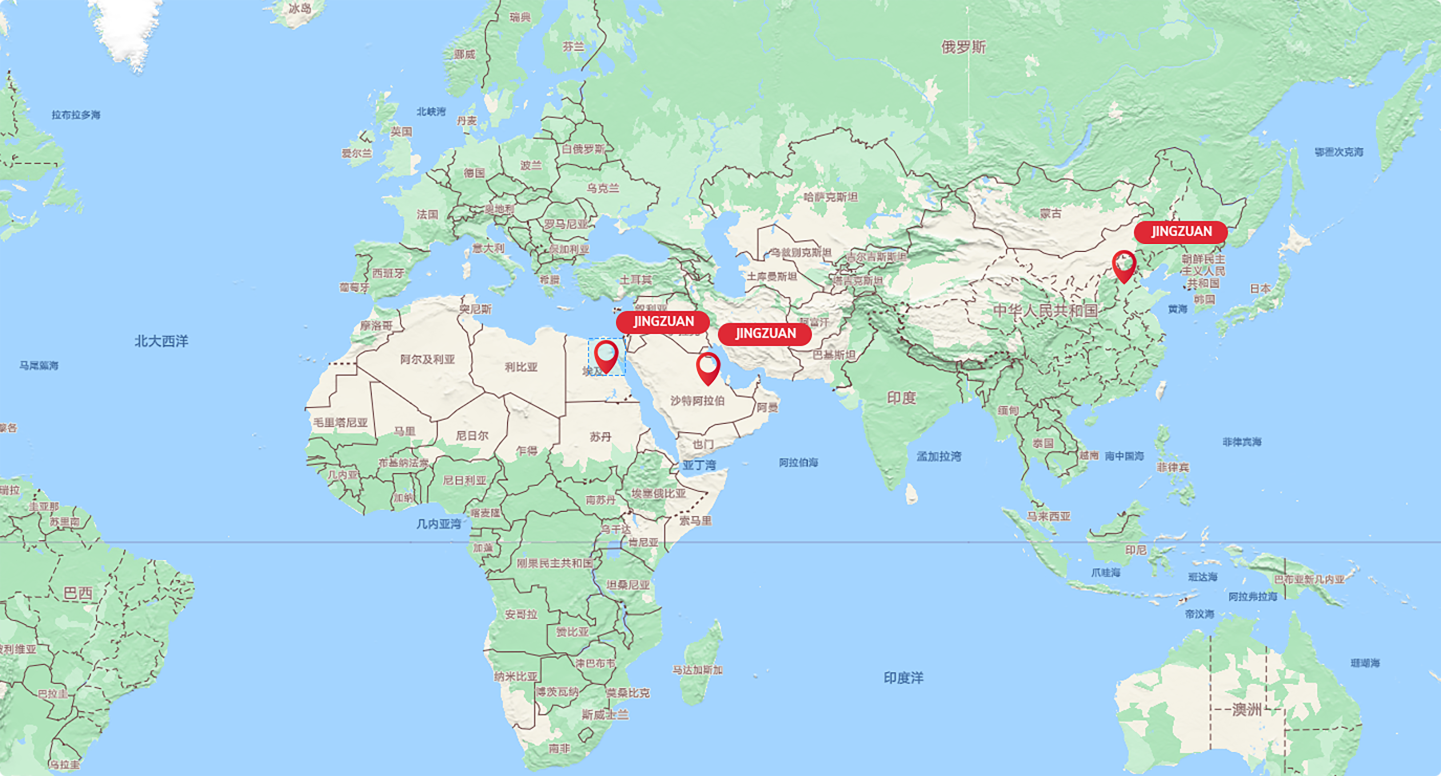

For instance, regions with abundant raw material resources and low labor costs, like Asia-Pacific, tend to offer more competitive prices compared to developed economies For instance, regions with abundant raw material resources and low labor costs, like Asia-Pacific, tend to offer more competitive prices compared to developed economies

For instance, regions with abundant raw material resources and low labor costs, like Asia-Pacific, tend to offer more competitive prices compared to developed economies For instance, regions with abundant raw material resources and low labor costs, like Asia-Pacific, tend to offer more competitive prices compared to developed economies redispersible polymer powder price. However, the quality of the product may vary, as stricter environmental and quality control regulations in developed countries can lead to higher production standards.

redispersible polymer powder price. However, the quality of the product may vary, as stricter environmental and quality control regulations in developed countries can lead to higher production standards. redispersible powder. The process involves spraying a liquid feedstock into a hot gas stream, which evaporates the solvent and leaves behind small, spherical particles. Coagulation, on the other hand, involves the aggregation of smaller particles into larger, more stable particles. This method is often used when a specific particle size distribution or shape is required. Fluidized bed granulation, finally, is a technique that combines drying and granulation in a single step. It is particularly useful for producing redispersible powders with good flow properties and high compactibility.

redispersible powder. The process involves spraying a liquid feedstock into a hot gas stream, which evaporates the solvent and leaves behind small, spherical particles. Coagulation, on the other hand, involves the aggregation of smaller particles into larger, more stable particles. This method is often used when a specific particle size distribution or shape is required. Fluidized bed granulation, finally, is a technique that combines drying and granulation in a single step. It is particularly useful for producing redispersible powders with good flow properties and high compactibility.Answer: HPMC viscosity is inversely proportional to temperature, meaning that viscosity increases as temperature decreases. When we refer to the viscosity of a product, it typically indicates the measurement of its 2% aqueous solution at a temperature of 20 degrees Celsius.

One of the most common queries we receive is what is HPMC and what are the health benefits of this particular polymer to our body. In this article, we will go through the basics of this wonderous substance and its uses.

HPMC, on the other hand, is Hydroxypropyl Methylcellulose. It is produced by alkali treatment of refined cotton and further etherified using epichlorohydrin and chloromethane as etherifying agents, resulting in a nonionic mixed ether of cellulose. The degree of substitution is typically between 1.2 and 2.0, and its properties vary based on the ratio of methoxy and hydroxypropoxy groups.

Its water retention properties prevent premature drying, improving workability and durability Its water retention properties prevent premature drying, improving workability and durability

Its water retention properties prevent premature drying, improving workability and durability Its water retention properties prevent premature drying, improving workability and durability hydroxy methyl cellulose. It also acts as a retarder, slowing down the setting time of cement, providing more flexibility during construction.

hydroxy methyl cellulose. It also acts as a retarder, slowing down the setting time of cement, providing more flexibility during construction. This dedication to excellence has earned HPMC Limited numerous accolades and recognition from regulatory bodies across the globe This dedication to excellence has earned HPMC Limited numerous accolades and recognition from regulatory bodies across the globe

This dedication to excellence has earned HPMC Limited numerous accolades and recognition from regulatory bodies across the globe This dedication to excellence has earned HPMC Limited numerous accolades and recognition from regulatory bodies across the globe hpmc ltd.

hpmc ltd.