Men's Rain Boots for Work A Comprehensive Guide

Felt bottom fishing boots are similar to wading shoes but offer additional ankle support and protection. These boots are designed to provide stability and comfort for anglers and outdoor enthusiasts who spend extended periods wading in water. The felt soles of these boots are effective at gripping various surfaces, making them a popular choice for fly fishing and other water-based activities.

This adaptability makes them a valuable addition to any wardrobe, bridging the gap between function and fashion This adaptability makes them a valuable addition to any wardrobe, bridging the gap between function and fashion

This adaptability makes them a valuable addition to any wardrobe, bridging the gap between function and fashion This adaptability makes them a valuable addition to any wardrobe, bridging the gap between function and fashion women's rain boots plaid.

women's rain boots plaid.

Hunting season is just around the corner, and as every hunter knows, having the right gear can make all the difference. One essential piece of equipment that every serious hunter should invest in is a pair of high-quality hunting boots. When it comes to hunting boots, one name that stands out is Thinsulate.

The Evolution of Sports Footwear

When it comes to fishing, having the right gear is essential for a successful outing. One critical piece of equipment that often goes overlooked is the footwear. Insulated waterproof fishing boots are not just a luxury; they are a necessity for any angler who wants to stay comfortable and dry throughout their fishing adventures.

Moreover, these boots can be beneficial to those who engage in outdoor activities, such as fishing, hiking, or camping. The waterproof and durable nature of men's safety Wellington boots provides an extra layer of protection for those who often find themselves in unpredictable weather. Being able to navigate wet and slippery terrains with confidence makes these boots an essential piece of equipment for outdoor enthusiasts.

Additional Maintenance Tips

Features of Stylish Sports Shoes

Drying wading boots are essential for anglers who require quick-drying and breathable footwear for wading in water during fishing activities. These specialized boots are designed to offer efficient water drainage and rapid drying, preventing discomfort from prolonged exposure to water. The breathable materials and innovative design make them an ideal choice for anglers seeking footwear that can withstand wet conditions and expedite the drying process.

Conclusion

In addition to its insulation properties, yellow tape plays a pivotal role in safety and hazard marking. Many industries utilize colored tape to demarcate hazardous areas, warn of potential dangers, or designate specific zones. The color yellow is universally associated with caution, making yellow insulation tape an effective tool for alerting individuals to be wary of risks in their environment.

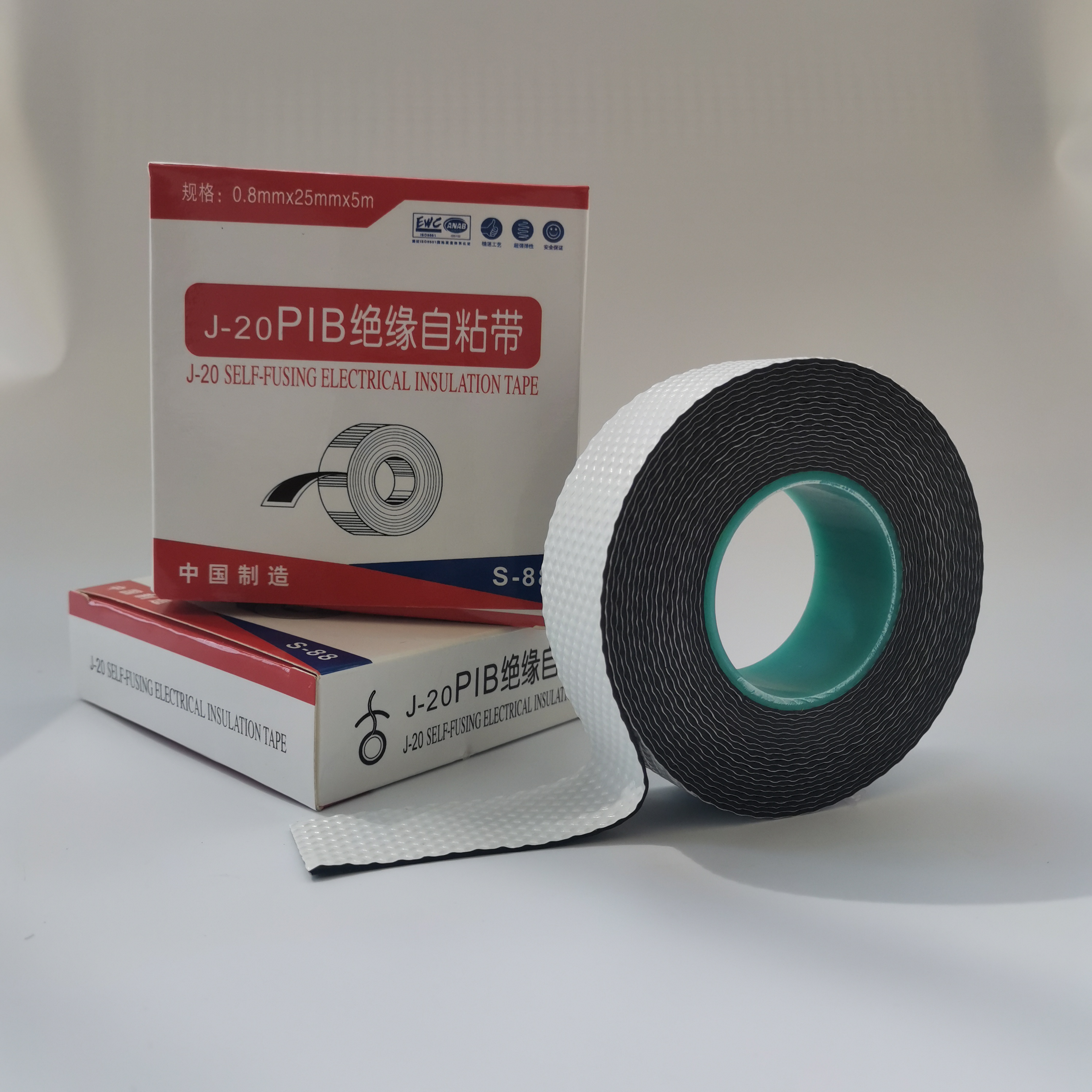

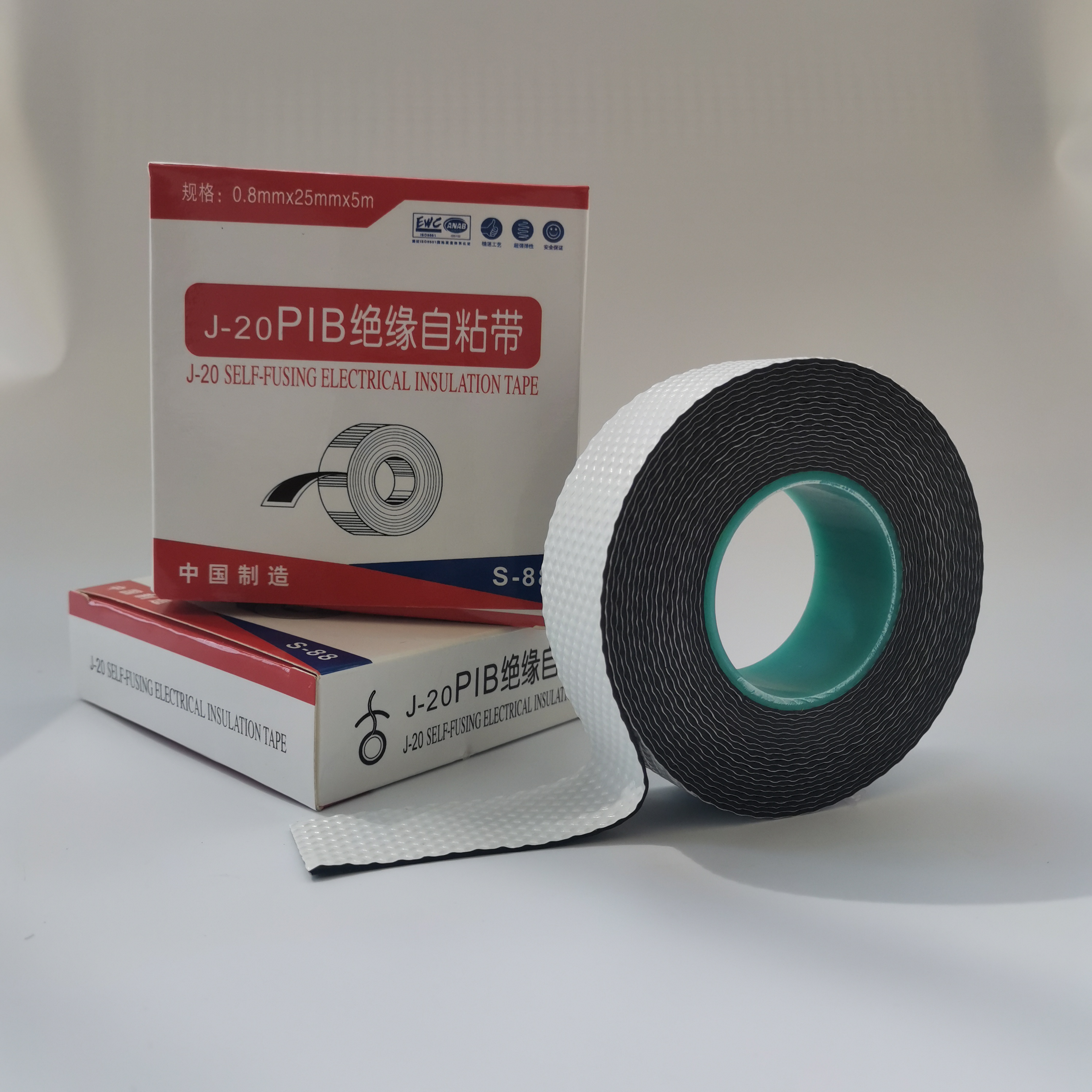

Silicone tape is self-fusing, which means it fixes to itself, creating a permanent bond. It does this because it is made of a specially cured rubber compound and a thin layer of silicone gel. It fuses within minutes to create a strong, insulating seal.

Butyl tape really is an all-rounder tape! It is perfect for use in the marine industry because of its strength, waterproof seal and compatibility with boat surfaces. Use butyl tape for boat hatches, portlights, and deck fittings.

rubber insulation tape. It is often used in plumbing for temporary repairs, in automotive for wire harnessing, and even in sports for injury prevention, demonstrating its versatility.

rubber insulation tape. It is often used in plumbing for temporary repairs, in automotive for wire harnessing, and even in sports for injury prevention, demonstrating its versatility.Features

A control box is an advanced electrical component that allows you to keep an eye on your connected devices and manage their operations. This physical interface comes with numerous high-end components with distinct roles key amongst them being monitoring and control.

Used for insulation and cable management, it can withstand extreme temperatures and harsh conditions encountered in space travel Used for insulation and cable management, it can withstand extreme temperatures and harsh conditions encountered in space travel

Used for insulation and cable management, it can withstand extreme temperatures and harsh conditions encountered in space travel Used for insulation and cable management, it can withstand extreme temperatures and harsh conditions encountered in space travel self annealing tape. The tape's self-repairing nature ensures the integrity of critical systems, enhancing overall safety.

self annealing tape. The tape's self-repairing nature ensures the integrity of critical systems, enhancing overall safety. This makes it ideal for long-term use in both residential and commercial settings This makes it ideal for long-term use in both residential and commercial settings

This makes it ideal for long-term use in both residential and commercial settings This makes it ideal for long-term use in both residential and commercial settings fireproof tape.

fireproof tape.

Hot-melt is a low-temperature melting plastic, which makes this adhesive have low temperature resistance. It also ages poorly (becoming brittle) and has low UV resistance. This rubber is used for low- to medium-duty carton sealing, low-temperature splicing as well as paper core starting applications.

Building codes and fire safety regulations mandate the use of fire seal tape in many applications to ensure the protection of occupants and property. Compliance with these regulations is not just a legal requirement; it is also a moral obligation to safeguard the lives of people who reside or work within the building. Inadequate sealing of fire-rated assemblies can lead to disastrous consequences during a fire emergency.

Insulating tape is also used for color-coding electrical wires. In complex wiring systems, it can be difficult to trace which wire connects to which component. By using different colors of insulating tape to wrap around the wires, technicians can easily identify which wires belong to which circuits. This makes troubleshooting and maintenance much easier and more efficient.