Major Producers:

The largest HPMC manufacturers are global chemical and pharmaceutical companies that have manufacturing capabilities in several countries. Among these, we can mention Dow Chemical Company, Ashland, and Shin-Etsu Chemical. These companies are known for their ability to produce high-quality HPMC suitable for a wide range of applications, including those requiring high standards such as the pharmaceutical and food industries.

Importance in the Gluten Free Food Industry:

In the context of gluten-free, the importance of HPMC has grown alongside the growing awareness and diagnosis of celiac disease and other gluten sensitivities. The need for gluten-free products that maintain the sensorial and structural qualities of traditional foods has driven the search for effective additives such as HPMC.

Current Considerations:

Although HPMC is widely used and generally considered safe, the current trend in the food industry is moving towards less processed and more natural ingredients. This may influence consumer perceptions of HPMC and other similar additives. However, its effectiveness as a gluten substitute in gluten-free preparations still makes it a valuable ingredient for many producers and consumers.

From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone

From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone

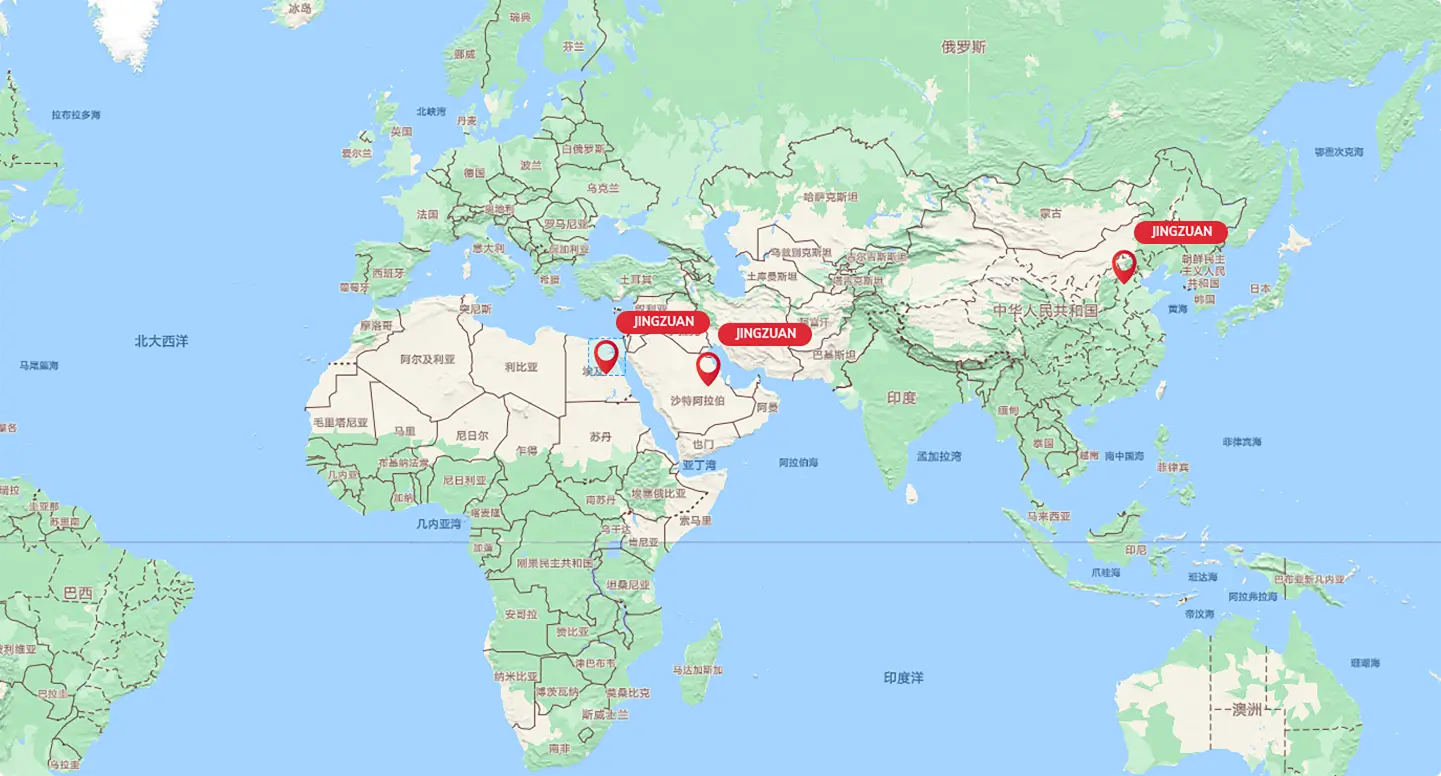

The region's preference for energy-efficient buildings and the growing demand for eco-friendly construction materials have created a conducive environment for the redispersible polymer powder market The region's preference for energy-efficient buildings and the growing demand for eco-friendly construction materials have created a conducive environment for the redispersible polymer powder market

The region's preference for energy-efficient buildings and the growing demand for eco-friendly construction materials have created a conducive environment for the redispersible polymer powder market The region's preference for energy-efficient buildings and the growing demand for eco-friendly construction materials have created a conducive environment for the redispersible polymer powder market Higher molecular weight HPMCP generally exhibits higher gelation temperatures, resulting in slower drug release rates Higher molecular weight HPMCP generally exhibits higher gelation temperatures, resulting in slower drug release rates

Higher molecular weight HPMCP generally exhibits higher gelation temperatures, resulting in slower drug release rates Higher molecular weight HPMCP generally exhibits higher gelation temperatures, resulting in slower drug release rates