Final Thoughts

Final Thoughts

When shopping for ladies' wading boots, several features are worth considering

Some models boast additional features such as integrated drainage systems, ensuring water doesn't pool inside if the bootie is submerged Some models boast additional features such as integrated drainage systems, ensuring water doesn't pool inside if the bootie is submerged

Some models boast additional features such as integrated drainage systems, ensuring water doesn't pool inside if the bootie is submerged Some models boast additional features such as integrated drainage systems, ensuring water doesn't pool inside if the bootie is submerged fly fishing neoprene booties.

fly fishing neoprene booties.

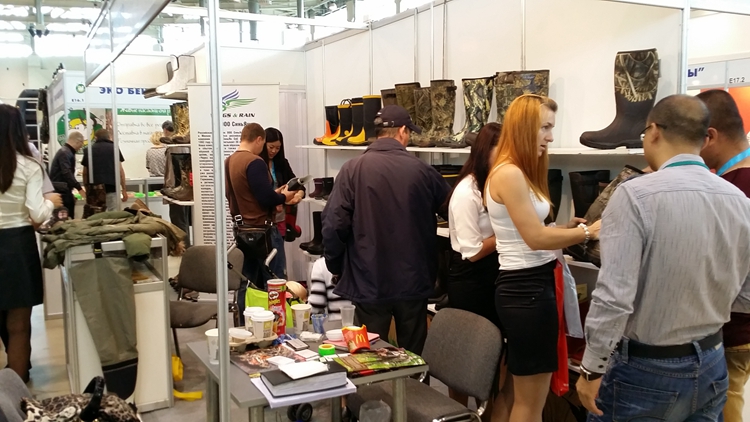

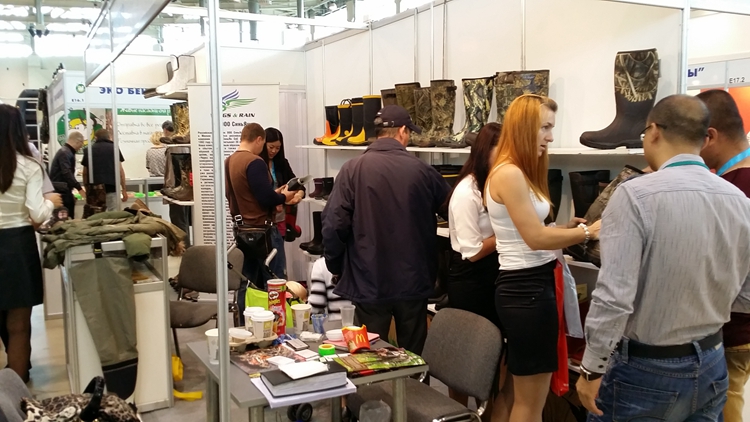

Fishing Rubber Boots The Perfect Companion for Anglers

From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone

From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone insulated waterproof rain boots. You can even find styles that are lined with faux fur for extra warmth and comfort.

insulated waterproof rain boots. You can even find styles that are lined with faux fur for extra warmth and comfort.

Stealth: The soft and supple material of neoprene dampens noise, enabling hunters to move quietly and undetected.

Waterproof camo boots are designed to provide hunters with protection from the elements while offering camouflage patterns to help them blend into their surroundings. These boots are typically constructed with waterproof materials such as Gore-Tex or other specialized membranes to keep the feet dry in wet conditions. The camo pattern helps hunters remain inconspicuous in the field, making them ideal for hunting in diverse terrains.

Brown hunting boots made of leather are the perfect choice for hunters looking for reliable and versatile outdoor boots. The rich brown color complements the natural outdoors, while the leather material provides durability and protection in rugged terrain. Designed to provide the necessary support, warmth and anti-slip features for a successful hunting experience, these boots combine style with practicality.

When it comes to fishing, having the right footwear is essential for comfort, protection, and performance. Fisherman's wellington boots are the ultimate choice for men seeking reliable, waterproof footwear for their fishing adventures.

Set a budget for your neoprene hunting boots and explore options within that range. While quality comes at a price, there are neoprene boots available at various price points to suit different budgets. Invest in the best quality boots you can afford to ensure durability and performance.

The Allure of Pink Waders A Unique Twist on Fishing Fashion

Durability and Protection

Today’s rubber water boots are more than just a simple design; they offer a range of functionalities that cater to various needs. First and foremost, they are made from waterproof materials that prevent water from seeping in, keeping your feet dry in rainy or wet conditions. The rubber material is also easy to clean, which is essential for anyone who frequently encounters mud or puddles.

From secure compartments for pliers, hooks, and lure boxes to spacious pockets for a phone or a small tackle bag, they provide ample storage space without hindering mobility From secure compartments for pliers, hooks, and lure boxes to spacious pockets for a phone or a small tackle bag, they provide ample storage space without hindering mobility

From secure compartments for pliers, hooks, and lure boxes to spacious pockets for a phone or a small tackle bag, they provide ample storage space without hindering mobility From secure compartments for pliers, hooks, and lure boxes to spacious pockets for a phone or a small tackle bag, they provide ample storage space without hindering mobility women's fishing overalls. Some overalls even include built-in rod holders or retractable tool keepers, adding an extra layer of convenience.

women's fishing overalls. Some overalls even include built-in rod holders or retractable tool keepers, adding an extra layer of convenience. types of sports shoes with names and pictures. Gym/Weightlifting Shoes

types of sports shoes with names and pictures. Gym/Weightlifting ShoesFinal Thoughts

Importance of Viscosity

The market for redispersible latex powders features several prominent manufacturers, each with its unique strengths. Companies like BASF, Dow Chemical, and Wacker Chemie are leaders in this sector, offering a broad portfolio of products that cater to both standard and specialized applications. These manufacturers invest heavily in research and development to innovate and optimize their products, addressing the evolving needs of the construction industry.

3. Construction In the construction industry, HPMC is used in adhesives, tile grouts, and mortars. Its water retention properties aid in achieving better adhesion even in challenging conditions, while its solubility characteristics enable easy mixing and application.

Overview of Redispersible Polymer Powders

One of the most significant advantages of redispersible polymer powders is their capability to enhance the mechanical properties of construction materials. For instance, when integrated into cementitious systems, they can help reduce the brittleness of the materials. This results in a more flexible final product capable of absorbing stresses without cracking. Moreover, RDPs improve the thin-layer application properties of mortars and adhesives, facilitating easier application and better aesthetics.

Conclusion

The food industry has also embraced hydroxyalkyl cellulose for its functional and stabilizing properties. It is often used as a food thickener, emulsifier, or stabilizer, ensuring that food products maintain their desired consistency and texture. HAC is particularly valuable in the formulation of gluten-free products, where it helps to mimic the texture and mouthfeel typically provided by gluten, thus improving the overall quality of gluten-free baked goods.

RDPs are produced by spray-drying aqueous dispersions of polymers. Upon addition to water, these powders can quickly rehydrate to form a fluid paste. When used in construction applications, RDPs improve the workability, adhesion, and flexibility of cement-based products such as mortars and renders. Additionally, they enhance properties like water resistance, durability, and mechanical strength, making them invaluable in various applications.

In summary, Hydroxypropyl Methylcellulose (HPMC) is an essential compound with a wide range of applications across several industries. From pharmaceuticals to food, construction, cosmetics, and agriculture, HPMC's unique properties facilitate improved performance and functionality in various products. As research and innovation continue to advance, the applications of HPMC are likely to expand, solidifying its role as a crucial ingredient in modern formulations. Its versatility and effectiveness make HPMC a vital component in addressing the demands of diverse industries, ultimately contributing to improved quality and sustainability.

The synthesis of hydroxyethyl cellulose is a carefully controlled process that requires precise conditions to ensure the desired level of substitution and product quality

. The reaction parameters, including temperature, pressure, reaction time, and catalyst concentration, must be optimized to achieve the desired DS and properties of the hydroxyethyl cellulose.

Understanding HPMC What Does It Stand For and Its Significance

Redispersible Polymer Powder An Overview

Viscosity, defined as a fluid’s resistance to flow, is a key property that influences the behavior of HPMC in various environments. Different applications require specific viscosity levels to achieve desired outcomes. For instance, in pharmaceuticals, the viscosity of HPMC affects drug release rates and bioavailability, whereas in construction, it can influence the workability and adhesion properties of cements and mortars.

2. Temperature The solubility of HPMC is temperature-dependent. Increasing temperature often enhances the rate of dissolution and the clarity of the solution. For example, heating water before adding HPMC can significantly expedite the blending process.

3. Construction

In the pharmaceutical industry, HPMC is commonly used as a binder, thickener, and film-forming agent in tablet formulations and controlled-release systems. Its ability to form gels and retain moisture makes it an ideal candidate for formulating extended-release medications. HPMC’s biocompatibility ensures that it is safe for human consumption, making it a preferred excipient for various drug delivery systems.

Moreover, RDPs can help achieve a smoother finish and improve the overall aesthetic quality of paints. They also contribute to lower VOC (volatile organic compounds) content, making formulations more environmentally friendly while maintaining performance.

HPMC also plays a vital role in clinical trials. The design and management of clinical trials generate extensive data that can be challenging to analyze. HPC can streamline this process by utilizing predictive modeling and simulations to identify optimal trial protocols, ensuring that researchers allocate their resources effectively. Furthermore, HPC can facilitate real-time data analysis during trials, enabling quicker adjustments based on emerging trends, which can ultimately accelerate the timeline for bringing new therapies to market.

2. Water Retention HEC has excellent water-retention capabilities, making it ideal for use in personal care products, such as moisturizers and hair conditioners, where prolonged hydration is desired.

The preparation of HPMC solutions is a straightforward process that involves careful selection of materials and precise execution of steps. Understanding the properties of HPMC and following the correct preparation method can significantly influence the performance of the final product in various applications. Whether used in pharmaceuticals, food products, or other formulations, a well-prepared HPMC solution can greatly enhance functional integrity and user experience.

What Are Mortar Bonding Additives?

In tile adhesive formulations, HPMC serves multiple functions

HPMC Limited Innovating Through Collaboration and Quality

In the pharmaceutical industry, hydroxyalkyl cellulose plays a crucial role in drug delivery systems

. It is often used as a thickening and gelling agent in topical medications, ensuring a uniform consistency that enhances the product's efficacy. Its biocompatibility and non-toxic characteristics further make it suitable for applications involving direct contact with the human body. Additionally, HAC is employed as a controlled-release agent, allowing for the gradual release of active ingredients over time, which significantly improves the therapeutic outcome of various medications.

High viscosity HPMC is a remarkable polymer that provides a wide array of benefits across various sectors, from pharmaceuticals to construction. Its ability to enhance viscosity, stability, and user experience makes it an invaluable component in product formulations. As industries continue to seek innovative solutions, high viscosity HPMC will play a vital role in meeting the demands for high-quality, effective, and sustainable products.

HPMC is utilized in various types of detergents, including liquid laundry detergents, dishwashing liquids, and all-purpose cleaners. In liquid laundry detergents, HPMC enhances cleaning efficiency by ensuring an even distribution of cleaning agents on fabrics. In dishwashing liquids, it provides thickness, enhancing the product's performance and consumer appeal. In general-purpose cleaners, HPMC can act as a suspending agent, allowing for the effective cleaning of dirt and grime without leaving residues.

The thermal and shear stability of hydroxyethyl cellulose is another noteworthy feature. Solutions of HEC can withstand varying temperatures and mechanical stress without significant changes to their viscosity. This resilience makes HEC suitable for industrial processes that involve heating and high shear forces.

4. Thermal Stability HPMC has good thermal stability, making it suitable for applications that require processing at elevated temperatures.

Moreover, HPMC is also finding applications in the realm of 3D printing. Its unique properties allow it to act as a support material, which can be removed easily after the printing process, facilitating the creation of complex structures. This innovative application is at the forefront of material science, showcasing the adaptability of HPMC in modern technologies.

What is Hydroxyethyl Cellulose Used For?

1. Low Viscosity Low viscosity HPMC usually ranges from 1000 to 6000 mPa.s. These grades are typically used when a thinner consistency is required, such as in liquid formulations or low-viscosity pastes. They offer excellent spreadability and are often used in applications where high dilution is necessary.

HEC also finds application in the food industry, where it serves as a food thickener and stabilizer. It helps improve the texture and viscosity of sauces, dressings, and dairy products. With a growing trend toward healthier and cleaner food options, hydroxyethylcellulose is often chosen for its efficient thickening properties without adding calories or altering the flavor of the product. Moreover, its ability to retain moisture makes it valuable in baked goods, extending shelf life without compromising on quality.

Hydroxypropyl methylcellulose (HPMC) is a versatile cellulose ether that has gained significant attention across various industries due to its unique properties and multifaceted applications. As a non-ionic polymer, HPMC is derived from cellulose, and its modification introduces different functional groups, making it suitable for a wide range of uses. The different grades of HPMC have varying physical and chemical properties, which allow them to cater to specific applications in pharmaceuticals, food preparation, construction, and many other fields.

The Versatile Uses of Hydroxyethyl Cellulose

Hydroxypropyl methylcellulose, commonly known as HPMC, is a cellulose-based polymer that has found widespread applications across various industries. This versatile compound is derived from natural sources and has undergone significant modification to enhance its functional properties, making it suitable for a range of applications, particularly in construction, pharmaceuticals, food, and cosmetics.

6. Final Mixing After cooling and adjusting the pH, briefly stir the solution to ensure homogeneity. This will eliminate any potential air bubbles and further improve the uniformity of the mixture.

Where to Buy Hydroxyethyl Cellulose

2. Construction Industry In construction, HEC is used in mortars, plasters, and self-leveling compounds as a thickener and a water-retention agent, improving workability and adhesion.

Despite the positive outlook, the redispersible polymer powder market faces certain challenges