For hydroxypropyl cellulose (E 463), the identified NOAEL corresponded to the highest dose 6,000 mg hydroxypropyl cellulose/kg bw per day (by gavage). The most relevant feeding studies with HPMC (E 464) were performed in rats which tolerated up to 10%, corresponding to 9,000 mg test item/kg bw per day. Rabbits tolerated up to 7,500 mg HPMC/kg bw per day administered via the diet (30 day exposure) and dogs up to 1,500 mg HPMC/kg bw per day, in either case being the highest tested dosages. More studies were conducted using sodium carboxy methylcellulose (E 466). The most relevant ones were conducted in rats, with NOAEL values ranging from 4,500 to 9,000 mg test item/kg bw per day (in all cases the highest dose tested). In these studies, some effects (caecum and colonic enlargement, urothelial hyperplasia, nephrocalcinosis, diffuse epithelial hyperplasia in the urinary bladder) were observed, however, not considered of toxicological concern: the findings in the gastrointestinal tract were considered to be a consequence of the accumulation of poorly absorbed water-soluble material and the findings in kidneys and urinary bladder were attributed to the up to fourfold higher concentration of sodium in the test diet compared with the basal diet. In one further study, rats were daily exposed (gavage) to doses equivalent to 0, 500, 2,500 or 5,000 mg/kg bw per day. Animals treated with ≥ 2,500 mg/kg bw per day had soft and pale faeces, which was attributed to the presence of test material and not considered of toxicological relevance. In the absence of any other adverse effects, also for this study, the identified NOAEL was the top dose (5,000 mg/kg bw per day).

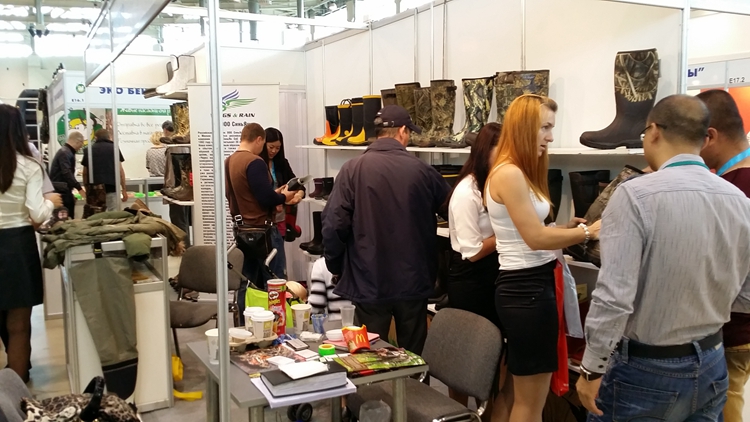

From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone

From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone

The final product is then dried, ground, and packaged for distribution The final product is then dried, ground, and packaged for distribution

The final product is then dried, ground, and packaged for distribution The final product is then dried, ground, and packaged for distribution

Some manufacturers specialize in producing specific types of HPMC, while others offer a wider range of products Some manufacturers specialize in producing specific types of HPMC, while others offer a wider range of products

Some manufacturers specialize in producing specific types of HPMC, while others offer a wider range of products Some manufacturers specialize in producing specific types of HPMC, while others offer a wider range of products It is also used as a non-ionic surfactant in drilling fluids for oil and gas exploration, enhancing the suspension of solids and preventing wellbore instability It is also used as a non-ionic surfactant in drilling fluids for oil and gas exploration, enhancing the suspension of solids and preventing wellbore instability

It is also used as a non-ionic surfactant in drilling fluids for oil and gas exploration, enhancing the suspension of solids and preventing wellbore instability It is also used as a non-ionic surfactant in drilling fluids for oil and gas exploration, enhancing the suspension of solids and preventing wellbore instability Its emulsifying properties make it suitable for use in salad dressings and sauces Its emulsifying properties make it suitable for use in salad dressings and sauces

Its emulsifying properties make it suitable for use in salad dressings and sauces Its emulsifying properties make it suitable for use in salad dressings and sauces