Men's Waterproof Camo Boots A Must-Have for Every Outdoor Enthusiast

Football boots, on the other hand, prioritize lightweight construction and stud patterns for better grip on the field Football boots, on the other hand, prioritize lightweight construction and stud patterns for better grip on the field

Football boots, on the other hand, prioritize lightweight construction and stud patterns for better grip on the field Football boots, on the other hand, prioritize lightweight construction and stud patterns for better grip on the field sport shoes description.

sport shoes description.

One of the standout features of spike fishing boots is their versatility. They can be used in a variety of fishing environments, whether it's freshwater lakes, rivers, or saltwater locations. Depending on the design, some boots even come with interchangeable spike systems, allowing anglers to customize their footwear based on the specific conditions of the day. This adaptability makes them a worthwhile investment for any serious angler who frequents different fishing terrains.

Hunting is not merely a sport; it's a pursuit that requires a combination of skill, strategy, and the right gear. Among the essential equipment for any hunter are their boots. When it comes to traversing rugged terrain quietly and comfortably, neoprene hunting boots stand out as a top choice. In this guide, we'll explore everything you need to know about these stealthy companions.

Conclusion

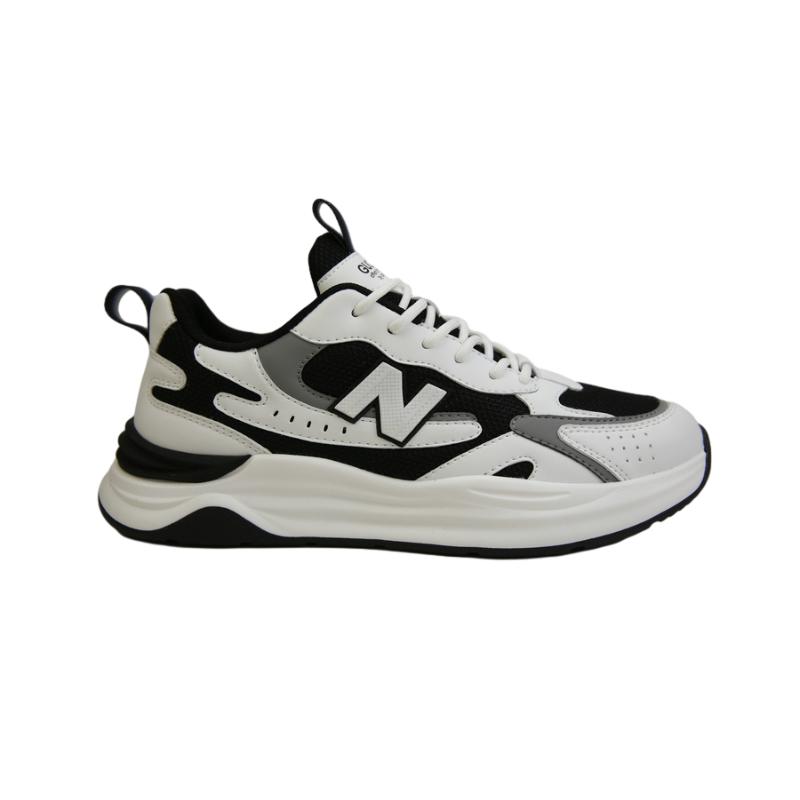

Versatility and Style

Sports shoes have transcended their original purpose of providing comfort and support during physical activities. Over the years, they have evolved into a significant aspect of fashion, culture, and even technology, leading to a substantial impact on their pricing. This article delves into the history, advancement, and current trends surrounding sports shoes and their pricing.

Neoprene fishing boots are designed with comfort in mind, featuring cushioned insoles and supportive construction that cradle the feet and provide all-day comfort. The soft and flexible material of neoprene conforms to the contours of the feet, offering a snug and comfortable fit without any uncomfortable pressure points. Whether standing on the deck of a boat, wading through streams, or walking along rocky shores, neoprene boots provide the support and cushioning anglers need to stay comfortable for hours on end.

Comfort and Flexibility

In summary, camo army boots, camouflage military boots, and camouflage tactical boots are crucial for military personnel and individuals engaged in tactical operations, providing the necessary support, protection, and camouflage to navigate challenging terrains and perform effectively in military and tactical settings.

Enhancing Safety on the Water

There are also more diverse designs in appearance.

In various industrial applications, the need for reliable sealing solutions is paramount, especially in environments that involve high pressure and rotating components. High pressure rotary seals are crucial in preventing fluid leakage, protecting machinery, and ensuring operational efficiency. This article aims to delve into the significance, applications, and advancements in high pressure rotary seals.

Finally, the 7% relates to the material composition and the durability of the seals. Oil seals are typically constructed from various compounds, including elastomers and polyurethane, each tailored for specific environmental conditions. A 7% threshold can indicate the percentage of material degradation that is acceptable over a defined lifespan. High-quality seals are engineered to endure extreme pressures and environmental challenges, maintaining their integrity even as their material composition undergoes wear.

Maintenance and Replacement

The operation of a hydraulic ram pump is based on the principles of momentum and inertia. Water flows through the drive pipe and enters the ram body. As the flow speed increases, the momentum of the water causes the waste valve to initially open. When the waste valve closes suddenly, the water's momentum generates a pressure spike in the system.

1. Oil and Gas In drilling operations and refineries, these seals are used in rotating equipment such as pumps and compressors, where high pressure is a constant factor. Their reliability is critical for maintaining safety and preventing spills.

1. Leak Prevention The primary function of seals in hydraulic cylinders is to prevent hydraulic fluid from leaking out of the cylinder. If seals fail, fluid can escape, leading to a loss of pressure, reduced efficiency, and potential damage to the hydraulic apparatus. This not only undermines performance but can result in costly repairs and downtime.

Oil seals are used in a wide range of applications, from automotive engines and transmissions to industrial machinery and household appliances. In vehicles, for instance, oil seals are commonly found in engines, differential housings, and wheel bearings. Their presence is critical in ensuring that these components operate efficiently and safely.

Signs You Need a Rebuild Kit

In conclusion, oil seals are indispensable components in many industrial and automotive applications. Oil seal manufacturers play a crucial role in producing these vital parts, ensuring machinery operates efficiently and safely. When selecting a manufacturer, consider their quality assurance practices, customization options, and material expertise to secure the best possible seals for your needs. Investing in high-quality oil seals not only enhances the performance of your machinery but also contributes to overall operational efficiency and safety.

Materials and Performance Factors

Regularly using a bottle jack repair kit can keep your tools in prime condition, ensuring both safety and efficiency. A well-maintained bottle jack can provide peace of mind, especially during critical applications, such as automotive repairs. Furthermore, being proactive about maintenance helps to identify issues before they escalate into more significant problems, saving time and money.

2. Remove the Boom Cylinder Start by detaching the boom cylinder from the excavator. This typically involves removing the pins and bolts that secure the cylinder to the boom and the attachment points. Use a hydraulic jack to support the cylinder as you loosen the connections.

In the world of heavy machinery and construction equipment, the efficiency and reliability of hydraulic systems are paramount. One crucial component that significantly impacts the performance of these systems is the boom cylinder seal kit. This article delves into the importance of boom cylinder seal kits, their components, and regular maintenance practices to ensure the optimal functioning of hydraulic cylinders.

4. Versatility These seals can be used in various applications across different industries, including automotive, aerospace, oil and gas, and manufacturing. Their adaptability makes them a preferred choice for engineers and manufacturers.

Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear

Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear hydraulic shaft seal. The choice of material depends on factors such as the type of fluid, operating pressure, and speed of the shaft.

hydraulic shaft seal. The choice of material depends on factors such as the type of fluid, operating pressure, and speed of the shaft.Applications

7. Install New Seals Carefully install the new seals into their respective grooves. Pay attention to ensure they are seated evenly and correctly.

Always refer to the manufacturer's guidelines or consult a professional if unsure Always refer to the manufacturer's guidelines or consult a professional if unsure

Always refer to the manufacturer's guidelines or consult a professional if unsure Always refer to the manufacturer's guidelines or consult a professional if unsure bottle jack repair kits.

bottle jack repair kits.Proper maintenance of wheel bearing grease seals is vital for optimal performance. Regular inspections are recommended to ensure seals are intact and functioning correctly. Signs of failing grease seals include visible grease leakage, noise from the bearing, or excessive heat during operation. If any of these signs are noted, it is crucial to address the issue promptly to avoid further damage.

Specifications

Hydraulic Cylinder Oil Seal

Importance of Oil Seals

hub oil seal. Their durability and reliability make them indispensable in ensuring the smooth functioning of these systems.

hub oil seal. Their durability and reliability make them indispensable in ensuring the smooth functioning of these systems.

1. Preparation Park the excavator on a flat surface and ensure it is turned off and secure. Use chalk or wedges to block the tracks to prevent movement.