The Evolution of Sports Footwear

The Evolution of Sports Footwear

From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone

From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone insulated waterproof rain boots. You can even find styles that are lined with faux fur for extra warmth and comfort.

insulated waterproof rain boots. You can even find styles that are lined with faux fur for extra warmth and comfort.

Affordable Ankle Rain Boots A Practical Choice for Wet Weather

Conclusion

youth breathable waders. Young anglers can choose from different colors and patterns to suit their personal preferences and style. Some waders even come with extra pockets and compartments for storing fishing gear and supplies, making them even more convenient for young anglers.

youth breathable waders. Young anglers can choose from different colors and patterns to suit their personal preferences and style. Some waders even come with extra pockets and compartments for storing fishing gear and supplies, making them even more convenient for young anglers.Fishing can be a rough-and-tumble activity, so durability is a key feature of any chest waders. Look for reinforced seams and materials that can withstand abrasions and punctures. After a day on the water, proper maintenance is crucial to extending the life of your waders. Rinse them with fresh water to remove any contaminants, and allow them to dry completely before storing them away to prevent mold and mildew.

These thoughtful additions not only aid in retaining body heat but also provide a sanctuary for cold fingers and toes These thoughtful additions not only aid in retaining body heat but also provide a sanctuary for cold fingers and toes

These thoughtful additions not only aid in retaining body heat but also provide a sanctuary for cold fingers and toes These thoughtful additions not only aid in retaining body heat but also provide a sanctuary for cold fingers and toes cold weather waders.

cold weather waders.

One of the most appealing aspects of camo canvas slip-on shoes is their unique aesthetic. The camouflage pattern, originally designed for military use, has transitioned into mainstream fashion, adding an edgy and adventurous vibe to any outfit. The combination of earthy tones and patterns means that camo shoes can easily complement a variety of clothing styles—from casual jeans and a t-shirt to a more urban, street-style look. This versatility makes them a favorite among fashion enthusiasts who appreciate both style and comfort.

To maximize the lifespan of your insulated waterproof boots, proper care and maintenance are essential. After each use, rinse off any dirt or saltwater, and allow the boots to dry naturally. Avoid using heat to dry them, as this can damage the waterproofing layer. Regularly check for signs of wear and tear, and promptly repair or replace them if needed.

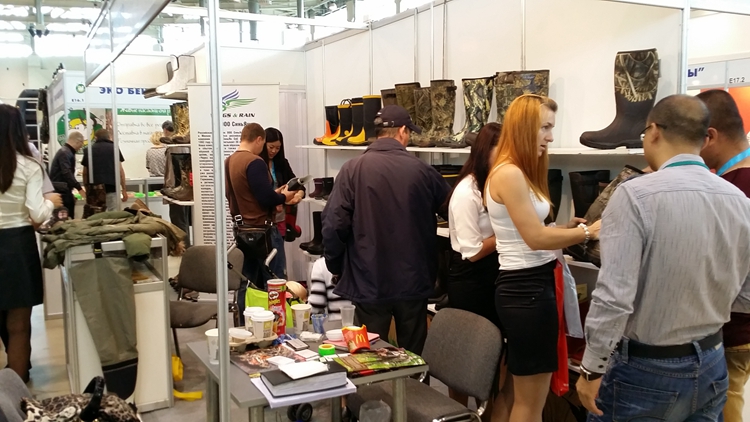

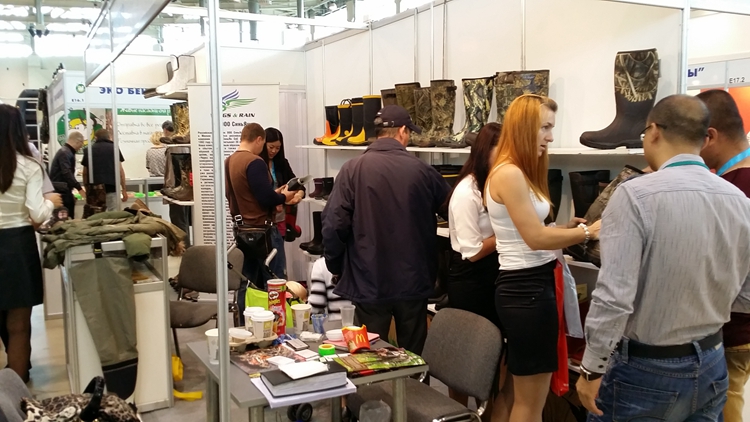

3、About production

Industrial oil seals are critical components used in a wide range of industrial machinery and equipment to prevent the leakage of lubricants and the ingress of contaminants. These seals play a vital role in maintaining the efficiency and longevity of industrial machinery by ensuring the proper containment of lubricants and protecting internal components from wear and damage. Industrial oil seals are utilized in various applications, including pumps, compressors, hydraulic systems, and manufacturing equipment.

There are many different materials used to manufacture oil seals.

Nitrile is the most widely used rubber (elastomer) and it’s recommended as the best for almost all standard applications. This is solely due to the fact that nitrile has some intrinsic properties, such as low cost and compatibility with most environments. Some of the general applications of nitrile are non-latex gloves, automotive transmission belts, footwear, gaskets, synthetic leather, hoses, o-rings, and oil seals.

How to Choose the Right Oil Seal

All are fitted with a spring to preload the sealing lip. All these types are for non-pressurised or low-pressure applications up to 0.5 bar for diameters of a limited size. For diameter of 500 mm or more, the maximum pressure is 0.1 bar. For higher pressures, special types or PTFE lip seals can be used.

spark plug in car engine. A lower heat range plug will have a cooler tip, which can improve fuel efficiency but may result in reduced power output and increased emissions. Conversely, a higher heat range plug will have a hotter tip, which can increase power output but may also lead to pre-ignition and engine damage if not properly managed.

spark plug in car engine. A lower heat range plug will have a cooler tip, which can improve fuel efficiency but may result in reduced power output and increased emissions. Conversely, a higher heat range plug will have a hotter tip, which can increase power output but may also lead to pre-ignition and engine damage if not properly managed. Conventional spark plugs are the most affordable but have the shortest lifespan Conventional spark plugs are the most affordable but have the shortest lifespan

Conventional spark plugs are the most affordable but have the shortest lifespan Conventional spark plugs are the most affordable but have the shortest lifespan spark plug for car. On the other hand, platinum and iridium spark plugs are more durable and efficient, though they come at a higher price.

spark plug for car. On the other hand, platinum and iridium spark plugs are more durable and efficient, though they come at a higher price.Regular inspection and replacement of oil seals are also necessary to prevent leakage and maintain the efficiency of the machinery. Over time, oil seals can wear out due to constant friction and exposure to harsh conditions, leading to leaks and potential damage to the equipment. By monitoring the condition of oil seals and replacing them as needed, operators can prevent costly downtime and repairs.

Standard 3760/3761

2. Temperature: Just like pressure, it is very important to choose the right seal that can withstand extreme heat or cold temperatures, depending on the operating environment of your application.

Overview of Oil Lip Seals

B

• ACM rubber