Brown Fishing Boots:

Another crucial aspect is the safety features integrated into many Wellington boots. Most models come equipped with steel toe caps or composite toe protection, shielding your toes from heavy objects, accidental falls, or any other workplace hazards. Additionally, many of these boots offer slip-resistant soles that provide excellent traction, reducing the risk of slips and falls on slippery surfaces—a critical feature for workers in dynamic environments.

Additionally, the lightweight nature of many rubber sole boots contributes to the overall comfort

. While providing ample protection, these boots do not add unnecessary weight, enabling workers to move freely and efficiently throughout their shifts.

Many spike fishing boots are designed to be waterproof, ensuring that your feet remain dry even in challenging conditions. This feature is crucial, as wet feet can lead to discomfort and even hypothermia in cooler weather. Additionally, waterproof materials help prolong the life of the boots, keeping them functional and looking new even after extensive use.

Some feature mesh overlays for enhanced ventilation, while others incorporate leather or synthetic materials for added durability Some feature mesh overlays for enhanced ventilation, while others incorporate leather or synthetic materials for added durability

Some feature mesh overlays for enhanced ventilation, while others incorporate leather or synthetic materials for added durability Some feature mesh overlays for enhanced ventilation, while others incorporate leather or synthetic materials for added durability full black sports shoes mens. The choice often depends on personal preference and intended usage.

full black sports shoes mens. The choice often depends on personal preference and intended usage.As the demand for men's green rain boots rises, various brands and designers are expected to expand their offerings, providing even more choices in terms of style, design, and price range. This growing trend signifies a shift in how men approach functional footwear, embracing styles that allow them to navigate the elements without sacrificing aesthetics.

In addition, many rubber boots come with insulation properties that keep feet warm in cold environments and cool in hot ones, thanks to their natural ability to regulate temperature In addition, many rubber boots come with insulation properties that keep feet warm in cold environments and cool in hot ones, thanks to their natural ability to regulate temperature

In addition, many rubber boots come with insulation properties that keep feet warm in cold environments and cool in hot ones, thanks to their natural ability to regulate temperature In addition, many rubber boots come with insulation properties that keep feet warm in cold environments and cool in hot ones, thanks to their natural ability to regulate temperature rubber slip resistant boots.

rubber slip resistant boots.3. Insulation Thickness Depending on the climate and the specific use, insulation thickness can vary. For colder regions or extended periods in chilly water, thicker insulation (around 5mm or more) may be advantageous. Conversely, thinner insulation may suffice for milder conditions.

The Allure of Pink Waders A Unique Twist on Fishing Fashion

For adults, they serve as a quirky accessory, reflecting their fun-loving spirit while keeping them comfortable and protected For adults, they serve as a quirky accessory, reflecting their fun-loving spirit while keeping them comfortable and protected

For adults, they serve as a quirky accessory, reflecting their fun-loving spirit while keeping them comfortable and protected For adults, they serve as a quirky accessory, reflecting their fun-loving spirit while keeping them comfortable and protected cute rubber rain boots.

cute rubber rain boots.When shopping for ankle rain boots, consider the following factors to ensure you make the best choice for your needs

Understanding Drain Covers

At first glance, the garbage drawer appears to be a chaotic blend of items that no longer serve an immediate purpose. It may contain an assortment of expired coupons, a collection of mismatched batteries, loose screws, and random stationery that lost its original mission long ago. Yet, buried within this apparent chaos lies a rich tapestry of memories and stories, waiting to be unearthed.

Aesthetic Appeal

Versatility in Use

Gully covers, often overlooked in urban planning and infrastructure management, serve a critical function in our drainage systems. Among various types of gully covers, the 6-inch gully cover stands out for its effective balance between strength and accessibility. It is essential to understand the purpose, benefits, and maintenance of these covers to ensure optimal drainage functionality in residential and commercial areas.

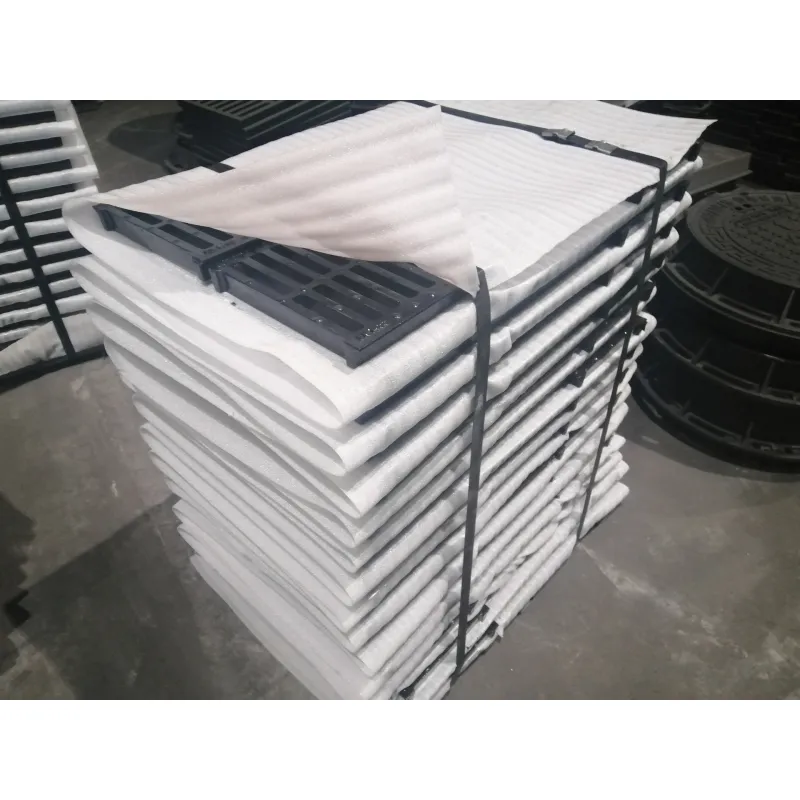

Below are the steps involved in making cast iron manhole covers.

In today’s ever-evolving urban environments, safety and security have become paramount considerations for city planners and architects. Among the many tools available to ensure public safety, lighted security bollards have emerged as an essential feature in urban design. These innovative structures not only serve a functional purpose but also enhance the aesthetic appeal of their surroundings, making them invaluable in creating safer and more vibrant public spaces.

Durability and Resistance

1. Residential Properties Homeowners install yard gullies in driveways, patios, and around foundations to prevent water pooling, which can lead to erosion and structural damage.

Although the covers are too large to be easily collectible, their ubiquity and the many patterns and descriptions printed on them has led some people to collect pictures of covers from around the world. According to Remo Camerota, the author of a book on the subject titled Drainspotting, 95% of Japanese municipalities have their own cover design, often with colorful inlaid paint.[2]

Understanding the Double Bin 80L

Why Choose Galvanized Pipe Repair Clamps?

The environmental advantages of using hanging dustbins extend beyond aesthetics and convenience. By reducing the amount of litter in public spaces, they contribute to the overall health of urban ecosystems. Less litter means a reduced risk of pollution in waterways, improved air quality, and a more pleasant environment for both residents and wildlife. Furthermore, the implementation of these dustbins can lead to a decrease in pest populations, as proper waste disposal minimizes food resources for creatures like rats and pigeons.

Moreover, moveable bollards contribute to the efficient management of traffic flow. In many urban centers, congestion is a persistent issue, often exacerbated by stationary barriers that disrupt the flow of vehicles. Moveable bollards offer a solution by allowing for the strategic redirecting of traffic. For example, during rush hours, certain roads can be closed to through traffic, encouraging vehicles to use alternative routes, thereby alleviating congestion in key areas. This adaptability not only improves traffic efficiency but also enhances air quality by reducing vehicle emissions in congested zones.

Parking and access control policies should also be developed in conjunction with the installation of manual rising bollards. Clear signage indicating when and how these bollards are to be raised or lowered can eliminate confusion among the public and help prevent unauthorized access.

- Ease of Maintenance With the bypass in place, operations can continue even while routine maintenance or inspections are performed on the main valve, reducing downtime.

In the heart of many landscapes lies a fascinating yet often overlooked feature the gully grid. This natural phenomenon, mostly found in areas with significant changes in elevation and rainfall patterns, represents a remarkable adaptation of the earth's surface to manage water flow, soil erosion, and ecological balance. Understanding the gully grid provides insight into environmental science, hydrology, and the interconnectedness of ecosystems.

One of the primary challenges associated with tree grilles and grates is ensuring that they do not hinder the growth of the trees they are meant to protect. As trees grow, their root systems expand, and it’s crucial that the design of the grilles and grates accommodates this natural growth. Innovative designs often include adjustable or flexible components that adapt as the tree matures, allowing for both protection and growth alignment.

Wooden bicycle racks are not only functional but also add a touch of style to any space. Made from sustainable materials, wooden racks provide a durable and aesthetically pleasing storage option for bikes of all shapes and sizes. Whether you live in a small apartment or a spacious house, a wooden bicycle rack can help you keep your bike organized and easily accessible.

Construction of manholes by precast concrete is a traditional method. These manhole frames are engineered in the segment in a factory located offsite. This method hence ensures quality and also facilitates quick installation. The manufactured precast manholes are assembled on the site.

Benefits of Commercial Bike Racks

One of the primary functions of manhole lid covers is to ensure public safety. These covers are designed to prevent accidents that could occur if someone were to accidentally fall into an open manhole. In busy urban areas, where foot traffic and vehicle movement are constant, a secure manhole lid is crucial. The weight of these covers, often made from heavy metals such as cast iron, ensures they remain in place under various conditions, including heavy traffic. Moreover, many modern covers are designed with locking mechanisms that provide additional security against removal or displacement.

Moreover, bollard guards are often used in securing high-profile buildings and public spaces, particularly in areas that may be susceptible to vehicle attacks. In recent years, the implementation of preventive measures against potential threats has become paramount. Bollard systems designed to withstand significant impacts offer a robust defense against unauthorized vehicles, further safeguarding individuals in crowded places. For instance, events held in bustling city centers often require the installation of temporary bollards to manage traffic control and enhance safety.

The Importance of Indoor Dustbins in Maintaining Cleanliness

Gate valves are integral components in the distribution and management of fluids in various industries, including water supply, wastewater treatment, and industrial applications. When it comes to High-Density Polyethylene (HDPE) pipes, the role of gate valves becomes even more significant due to the unique properties of HDPE and its widespread use in modern infrastructure.

- Size and Compatibility The gate valve must match the diameter of the HDPE pipe it is intended to be used with. Compatibility in terms of connection type (such as flanged or threaded) is also essential to ensure a secure fit.

Additionally, Klargester manhole covers are designed with safety in mind. Many models incorporate anti-slip surfaces and secure locking mechanisms to prevent accidental openings, thereby reducing the risk of accidents. This emphasis on safety is vital in urban settings where heavy foot and vehicle traffic is common. Moreover, these products often come with visibility features, such as reflective surfaces, that improve their visibility at night or in poor weather conditions, further enhancing public safety.

Another essential aspect of the 120L dustbin is its environmental impact. With rising concerns over climate change and pollution, the importance of reducing waste cannot be overstated. Larger bins enable more efficient collection schedules, as waste can be collected less frequently, leading to reduced fuel consumption and lower emissions from waste collection vehicles. Additionally, when waste is properly sorted and disposed of in a timely manner, it can be diverted away from landfills and sent to appropriate recycling and composting facilities, further minimizing environmental harm.

Ergonomic Design for Comfort

If you’re unsure whether your property needs a manhole cover, there are a few things you can look for:

At first glance, a manhole cover may seem like a mundane and utilitarian object, merely serving as a protective lid for underground utilities and sewer systems. However, if we take a moment to delve deeper, we unveil a fascinating world that exists beneath our feet, intricately linked to the infrastructure of urban life. The theme manhole cover inside invites us to explore not only the physical aspects of these covers but also the rich tapestry of history, engineering, and societal impact they embody.

2. Debris Control The cover guards against the entry of leaves, litter, and other debris that can clog the drainage system. When debris accumulates in the gully, it can lead to blockages that prevent the smooth flow of water, aggravating flood risks. The 200mm size offers a balance, allowing for sufficient flow while still capturing significant amounts of debris.

In conclusion, drain covers are an integral part of any driveway, contributing to water management, safety, and the overall aesthetics of your property. By understanding their importance and the types available, as well as adhering to a regular maintenance schedule, homeowners can protect their driveways from water damage and ensure a safe environment for all who use it. Invest in quality drain covers and prioritize their upkeep to enjoy a functional and attractive driveway for years to come.

(vi) Odor Control: Manholes can emit unpleasant odors due to the presence of gases. To minimize odors in residential spaces, consider implementing odor control techniques, such as installing odor-reducing inserts or chemical treatments.

Moreover, these covers often feature a textured surface to provide traction and prevent slipping, particularly in wet conditions. This is crucial for pedestrian safety, especially in urban areas where foot traffic is heavy. They are also designed to be stackable and lightweight for easier transportation and installation, even in densely populated or high-traffic areas.

In conclusion, the bollard line is a multifaceted concept that encapsulates the intersection of safety, functionality, and aesthetics in urban and maritime environments. Whether guiding pedestrians in a bustling city or securing vessels at a marina, the thoughtful implementation of bollard lines plays a vital role in fostering safe, inviting, and visually engaging spaces. As cities continue to grow and evolve, the significance of the bollard line will remain a foundational aspect of urban planning and design, reflecting the ongoing dialogue between functionality and creativity in our built environments.

Cast Iron Manhole Covers

Manhole covers are made with different materials such as cast iron, ductile iron, concrete and in some cases, with glass reinforced plastic (GRP). Cast iron manhole covers are preferred because they are strong, cheap and easy to cast. A heavy manhole cover is essential to ensure that the cover does not get dislodged by pressure from gasses released in the drains and also from sucking pressure of fast moving vehicles. Unpainted cast iron inherently possesses rust resisting properties that make it an excellent choice to ensure best performance and long service life. Though other materials for manhole covers are available, the strength of cast iron cannot be overstated when it comes to resisting earth and pavement pressures.

Moreover, combining efforts from various agencies can help streamline the maintenance process. Creating a central reporting system that allows multiple utilities and the city to coordinate their efforts can significantly enhance response times to repairs and maintenance.

Additionally, regional differences in pricing can arise due to local market conditions, tariffs, and labor costs. For example, the price of gate valves can vary significantly between developed and developing countries. In regions with lower labor costs and abundant raw materials, valves may be priced more competitively than in regions where manufacturing expenses are higher. This disparity can be critical for businesses looking to source gate valves on a budget while maintaining quality and compliance with industry standards.

The Role of Grates

1. Oil and Gas In the oil and gas industry, gate valves are essential for controlling the flow of crude oil, natural gas, and other hydrocarbons. These valves can handle high-pressure environments and are often used in upstream (production), midstream (transportation), and downstream (refining) applications.

Conclusion