Having thus described the origin and uses of the pigment, we now come to the question, what is lithopone? It is, in short, a chemical compound usually consisting of 30.5 per cent zinc sulphide, 1.5 per cent zinc oxide and 68 per cent barium sulphate, but these proportions vary slightly in the different makes. Lithopone of this composition is sold as the highest grade, either as red seal or green seal, as it best suits the idea of the manufacturer. Many manufacturers, especially in Europe, sell and also export other brands under other seals, containing 24, 20, 18 and as little as 12 per cent of zinc sulphide with very small percentages of zinc oxide, the balance being usually barium sulphate, but sometimes certain portions of China clay or gypsum (calcium sulphate) or whiting (calcium carbonate). Such brands are not a chemical compound, but mechanical mixtures of the chemically compounded lithopone and the admixtures referred to.

The result is a wader that withstands the rigors of fishing while keeping the wearer dry and content The result is a wader that withstands the rigors of fishing while keeping the wearer dry and content

The result is a wader that withstands the rigors of fishing while keeping the wearer dry and content The result is a wader that withstands the rigors of fishing while keeping the wearer dry and content This is particularly important for those who work outdoors or in refrigerated environments This is particularly important for those who work outdoors or in refrigerated environments

This is particularly important for those who work outdoors or in refrigerated environments This is particularly important for those who work outdoors or in refrigerated environments

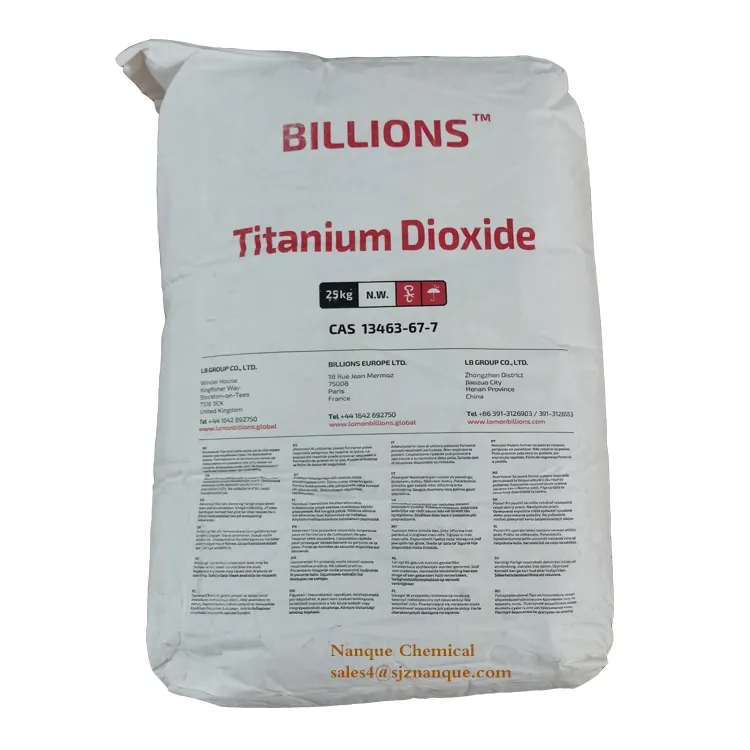

Some of the most well-known manufacturers include DuPont, Cristal Global, and Huntsman Corporation Some of the most well-known manufacturers include DuPont, Cristal Global, and Huntsman Corporation

Some of the most well-known manufacturers include DuPont, Cristal Global, and Huntsman Corporation Some of the most well-known manufacturers include DuPont, Cristal Global, and Huntsman Corporation