Comfort for Long Fishing Sessions

Comfort for Long Fishing Sessions

Comfort is also an important factor to consider when choosing fishing boots

. You may be spending long hours on your feet while fishing, so having a pair of boots that fit well and provide good support can help prevent fatigue and foot pain. Look for boots with cushioned insoles and ergonomic designs that will keep your feet comfortable throughout the day.

In conclusion, style athletic shoes have become a cultural phenomenon, epitomizing the intersection of fashion and function. Their rise reflects a broader societal shift towards valuing comfort, versatility, and self-expression. As athletic shoes continue to adorn the feet of fashion-forward individuals worldwide, it is apparent that the line between sportswear and everyday style has faded, permanently altering the landscape of footwear fashion. Whether hitting the gym or hitting the streets, style athletic shoes remain a powerful symbol of contemporary fashion, showcasing a blend of innovation, flair, and practicality.

Many men's rain boots come equipped with additional features such as cushioned insoles, non-slip soles, and breathable linings, enhancing comfort for extended use. With the right pair, men can tackle outdoor adventures, gardening tasks, or daily errands with confidence, knowing their feet are protected from the elements.

Steel toe insulated rubber work boots are not limited to harsh industrial settings; they are also popular in numerous other fields. For instance, agricultural workers frequently opt for these boots, as they provide necessary protection against sharp objects while also keeping their feet dry when working in wet fields. Similarly, maintenance professionals can benefit from the versatility and safety features these boots offer, making them an all-around choice for people in physically demanding jobs.

A good grip is vital for maintaining stability and preventing slips and falls, particularly on uneven or slippery surfaces. Look for neoprene boots with aggressive tread patterns and durable outsoles that offer reliable traction on various terrains, including mud, rocks, and snow.

In today's environmentally conscious world, the sustainability of materials is a significant consideration for many industries. Stainless steel is 100% recyclable, which means that using stainless steel floor grating contributes to a more sustainable building practice. Its long lifespan also reduces the need for frequent replacements, which in turn minimizes waste and environmental impact over time. Companies that prioritize sustainability can enhance their reputation and appeal to a more eco-conscious customer base by choosing stainless steel solutions.

1. Material Construction The construction material greatly affects the cost. Vessels made from higher grades of stainless steel or specialized alloys designed for corrosive environments tend to be more expensive due to their durability and capability to withstand extreme conditions.

Fiberglass privacy fences are available in a variety of styles, colors, and textures, allowing homeowners to choose a design that complements their property. Whether you prefer a sleek modern look or something more traditional, you’ll find fiberglass fencing options that meet your aesthetic needs. This versatility means you don’t have to sacrifice style for functionality; instead, you can enhance your home’s curb appeal while enjoying the benefits of increased privacy.

In addition to safety, modular handrails can significantly enhance the functionality of a space. For instance, they can be integrated with other elements such as glass panels, lighting features, or even automated systems that can provide additional support in public environments. This adaptability makes them ideal for both residential staircases and commercial buildings.

GFRP rebar is being utilized in various projects, from bridges and highways to residential buildings and foundations. Its application is expanding across the globe, especially in regions where infrastructure resilience is a critical concern. As the construction industry continues to prioritize sustainability and long-term durability, GFRP rebar is poised to become a standard material in the toolkit of engineers and architects.

1. Durability One of the most significant benefits of FRP trench drains is their longevity. FRP materials are resistant to corrosion and decay, which is especially advantageous in areas exposed to chemicals, salt, and moisture. This means lower maintenance costs and longer service life compared to traditional drainage solutions.

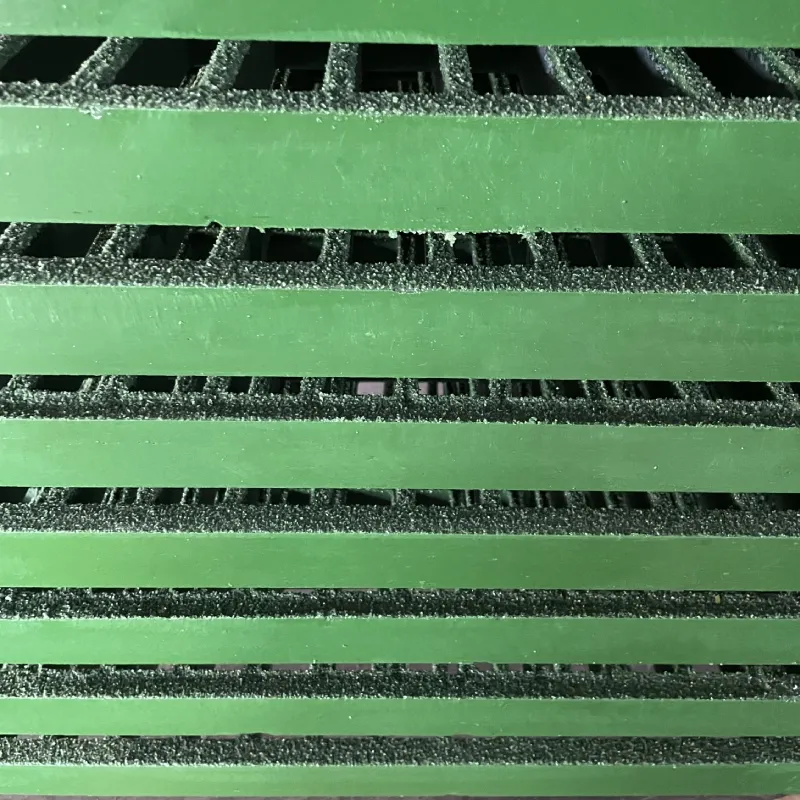

Features of 38mm GRP Grating

As industries face increasing pressure to adopt sustainable practices, stainless steel filter vessels offer an environmentally friendly alternative. Unlike plastic filters that may require frequent replacement, stainless steel vessels are durable and can be reused for many years. Their recyclability further enhances their appeal as a sustainable choice.

4. Customizable These tanks can be tailored to meet specific requirements. Whether you need a tank for emergency water supply, agricultural use, or industrial processes, SMC panel tanks can be designed in various shapes and sizes to accommodate diverse needs.

5. Location and Transportation The geographic location of the buyer and the manufacturer can also affect prices. Transportation costs for large, heavy tanks can be significant, especially for remote or hard-to-access areas. Additionally, local market conditions or supply chain issues may impact pricing.

Pressure tanks are an essential component in various industries, providing a reliable method for storing liquids and gases under pressure. These tanks are designed to withstand internal pressures that exceed atmospheric levels, ensuring the safe and efficient management of fluids ranging from potable water to industrial chemicals. In this article, we will explore the functionality of pressure tanks, their applications, and the importance of regular maintenance.

6. Health and Safety Standards GRP tanks are designed to meet rigorous health and safety standards, ensuring that the stored water remains safe for consumption. The smooth inner surface minimizes the growth of algae and bacteria, which can be a concern in water quality management.

Eco-Friendly Option

5. Environmental Friendliness SMC panel tanks are recyclable, making them a more sustainable option compared to traditional steel or concrete tanks. Their production process also generates less waste, aligning with modern environmental standards.

In conclusion, fiberglass storage tanks offer a robust, reliable, and cost-effective solution for a variety of storage needs. Their advantages, such as corrosion resistance, durability, and customization, make them an increasingly popular choice across different industries. Businesses interested in purchasing fiberglass storage tanks should consider their specific requirements, environmental conditions, and regulations to make an informed decision.

Fiberglass rod manufacturers play a crucial role in supplying essential materials across various sectors. Their commitment to quality and innovation ensures that industries can rely on fiberglass rods for a wide range of applications. As sustainability and technology continue to shape the market landscape, these manufacturers are poised to lead the way in providing innovative solutions that meet current and future demands. In doing so, they not only contribute to the efficiency and effectiveness of industries but also to a more sustainable future.

2. Automotive Sector The automotive industry utilizes CHS tubes in vehicle frames and body components. Their lightweight nature combined with high tensile strength contributes to improved fuel efficiency and safety in vehicles.

Durability and Strength

Applications of Structural FRP

The applications of structural FRP are expanding across various sectors, addressing the specific needs of modern infrastructure and construction. Some of the notable applications include

Challenges and Future Outlook

FRP materials are renowned for their durability. Unlike wood, which can rot or degrade over time, or metal, which can corrode, FRP is designed to stand the test of time. The resistance to chemical spills makes FRP stair treads particularly useful in environments such as factories, warehouses, and laboratories. They can endure extreme weather conditions, making them suitable for both indoor and outdoor installations. The longevity of FRP treads translates to cost savings over time, as they require less frequent replacement and maintenance.

Fiberglass rods are primarily made from glass fibers, which are woven together and then coated with a resin to form a solid, durable rod. This unique composition provides an array of benefits, making fiberglass rods suitable for various applications. Unlike traditional materials like steel or wood, fiberglass is lightweight, making it easier to handle and install. Additionally, it does not corrode, which extends its lifespan and reduces maintenance costs for infrastructure and equipment.

1. Industrial Facilities In industries where chemical spills are a concern, FRP drain channels are often employed to manage and redirect hazardous liquids safely. Their resistance to corrosive substances makes them a preferred choice for chemical plants and manufacturing facilities.

The RO system represents a pivotal advancement in resource and operational management. By focusing on reliable operations and efficient resource utilization, organizations can significantly enhance their performance whilst minimizing costs. As technology continues to evolve, the principles and practices associated with the RO system will undoubtedly play an increasingly vital role in shaping the future of various industries. Embracing this system will not only lead to improved operational effectiveness but also foster innovation and growth in different sectors. For those looking to stay competitive in an ever-evolving landscape, understanding and implementing the RO system is not just beneficial—it is essential.

Applications of Pentair FRP Vessels

Exploring the Cost and Benefits of FRP Underground Water Storage Tanks

Hard water is characterized by the presence of dissolved minerals, primarily calcium and magnesium. While hard water is not necessarily harmful to health, it can have negative effects on household appliances, skin, and hair. In appliances like dishwashers and washing machines, hard water can lead to limescale build-up, reducing efficiency and lifespan. Additionally, hard water may leave deposits on dishes, making them appear cloudy and unclean.

In recent years, the use of Fiber Reinforced Polymer (FRP) materials has gained significant traction in various construction and engineering applications. Among the innovative uses of FRP is in the fabrication of stair systems. FRP stair systems are rapidly becoming the preferred choice for many developers and architects due to their exceptional characteristics, including durability, lightweight nature, and resistance to corrosion. This article delves into the advantages of FRP stair systems, their applications, and factors to consider when choosing them for your next project.

In the maritime and industrial sectors, the importance of choosing the right vessel for specific applications cannot be understated. Among the various types of vessels available, Fiber Reinforced Plastic (FRP) vessels have emerged as a popular choice due to their durability, corrosion resistance, and lightweight properties. Over recent years, one classification that has drawn attention is the 1665 FRP vessel, known for its specific design and operational capabilities. Understanding the pricing of these vessels involves considering several factors that influence cost.

Heavy Duty Bar Grating An Essential Component in Industrial Applications

The Versatility and Durability of Fiberglass Fence Rods

3. Aesthetic Appeal The smooth, round shape of CHS steel tubes lends a modern aesthetic to buildings and structures. They can also be designed in various finishes to complement architectural styles, making them an attractive choice for visible structural elements.

In an age where sustainability is paramount, galvanized sectional water tanks provide an environmentally friendly solution. The galvanization process uses fewer chemicals compared to other tank manufacturing methods, and the tanks can be recycled at the end of their lifespan. Moreover, these tanks can be utilized for rainwater harvesting systems, promoting water conservation and reducing reliance on municipal supply.

Conclusion

On average, the cost of FRP grating ranges from $3 to $12 per square foot. Basic options without specialized features can be found closer to the $3 to $5 range, while high-performance grating with customized features may reach up to $12 or even higher. It's essential for contractors and purchasers to compare options and seek multiple quotes to ensure they receive competitive pricing.

5. Ease of Maintenance The smooth surface of FRP tanks makes them easy to clean and maintain. Additionally, the material does not promote biological growth, which is a common concern in the storage of liquids.

One of the most significant advantages of sectional steel tanks is their customizable design. Manufacturers can fabricate tanks in various sizes and shapes, which means that companies can tailor the tank to fit their available space and specific requirements. This adaptability is particularly beneficial for facilities with space constraints or unusual layouts. Whether you need a small tank for a village water supply or a large tank for industrial use, sectional steel tanks can be designed to meet those needs efficiently.

3. Lightweight and Easy to Install The lightweight nature of GRP makes it easy to handle and install. This characteristic reduces labor costs and time during installation. The fencing can be easily transported and manipulated, allowing for a seamless installation process, whether for temporary setups at events or permanent fixtures in residential areas.

Conclusion

2. Lightweight FRP drain channels are significantly lighter than concrete or metal alternatives, making them easier to transport, handle, and install. This feature is particularly advantageous in projects where reducing labor costs and installation time is critical.

Understanding GFRP Grating A Versatile Solution for Modern Applications

In conclusion, FRP bridge deck panels represent a significant advancement in civil engineering and infrastructure development. Their lightweight, durable, and sustainable properties make them an ideal alternative to traditional bridge materials. As technology continues to evolve and more case studies emerge demonstrating their efficacy, it’s likely that FRP materials will play an increasingly prominent role in the design and construction of future bridges, offering enhanced safety, efficiency, and environmental stewardship.

GRP grating specification refers to the detailed requirements and standards that govern the design, manufacture, and installation of GRP (Glass Reinforced Plastic) gratings

.2. Corrosion Resistance FRP materials are inherently resistant to corrosion caused by environmental factors and chemicals, making them ideal for use in areas prone to moisture, salt spray, or industrial chemicals. This characteristic significantly extends the lifespan of the panels without the need for frequent replacements.

Moreover, carbon filter vessels are eco-friendly. Activated carbon can be derived from renewable resources such as coconut shells, wood, or peat, making it a sustainable choice for water treatment. Furthermore, when the activated carbon becomes saturated with contaminants, it can often be regenerated or replaced, reducing the need for new materials and lessening environmental impact.

1. Corrosion Resistance One of the most significant advantages of FRP tanks is their resistance to corrosion. Unlike traditional materials such as steel, FRP does not rust or corrode when exposed to harsh chemicals, making it ideal for storing aggressive fluids. This property extends the lifespan of tanks and reduces maintenance costs significantly.

Applications of FRP Decking

Galvanized Steel Water Tanks for Sale The Durable Solution for Water Storage

Understanding the 2472 FRP Vessel A Key Innovation in Composite Technology