In addition to improving the bond between the cement and the surface, cement bonding additives can also help to increase the workability and durability of the cement mixture. By adding the right additive to the mix, contractors can achieve a smoother and more consistent finish, as well as a longer-lasting bond that is resistant to damage from harsh weather conditions and heavy traffic.

What is it: HPMC is a chemically modified cellulose polymer that is off-white in color and considered safe for human consumption. It is most commonly used as an alternative to gelatin and gluten in vegan-friendly products.

1. Pharmaceutical Industry One of the most significant uses of HPMC 4000 is in the pharmaceutical sector, where it is employed as a binder in tablet formulations, a film-coating agent, and a controlled-release encapsulating agent. It aids in achieving the desired release profile of active ingredients, ensuring efficacy and patient compliance.

แผ่น hpmc.

Moreover, HPMC is compatible with a wide range of additives, allowing for the customization of mortar formulations to meet specific performance requirements. Whether it involves enhancing adhesion, workability, or flexibility, HPMC can be used alongside other polymers or chemical additives to create tailored solutions that address the unique challenges of various construction environments. This versatility makes HPMC a preferred choice among contractors and manufacturers looking to optimize their mortar products.

The solubility characteristics of HPMC make it suitable for a variety of applications

One key responsibility of HPMC manufacturers is to maintain the consistency and purity of their products. Even slight variations in the composition of HPMC can lead to significant differences in performance. Therefore, manufacturers must implement rigorous quality control measures to keep their production inline with both domestic and international standards, such as FDA regulations for pharmaceutical applications.

In addition to its thickening properties, HEC has excellent film-forming capabilities, making it a valuable ingredient in coatings and films. HEC can also provide binding and stabilizing effects in various formulations, improving the overall performance and shelf life of the product.

hydroxyéthyl cellulose

Understanding HPMC

MHEC is derived from natural cellulose, making it a semi-synthetic polymer. The manufacturing process typically involves the modification of cellulose through methylation and hydroxyethylation. This process enhances the solubility of cellulose in water and provides a range of functional properties that are highly sought after in industrial applications. MHEC can be produced in various viscosity grades, allowing manufacturers to customize the product according to specific requirements.

Firstly, they enhance thermal protection, a critical factor in cold water conditions Firstly, they enhance thermal protection, a critical factor in cold water conditions

Firstly, they enhance thermal protection, a critical factor in cold water conditions Firstly, they enhance thermal protection, a critical factor in cold water conditions

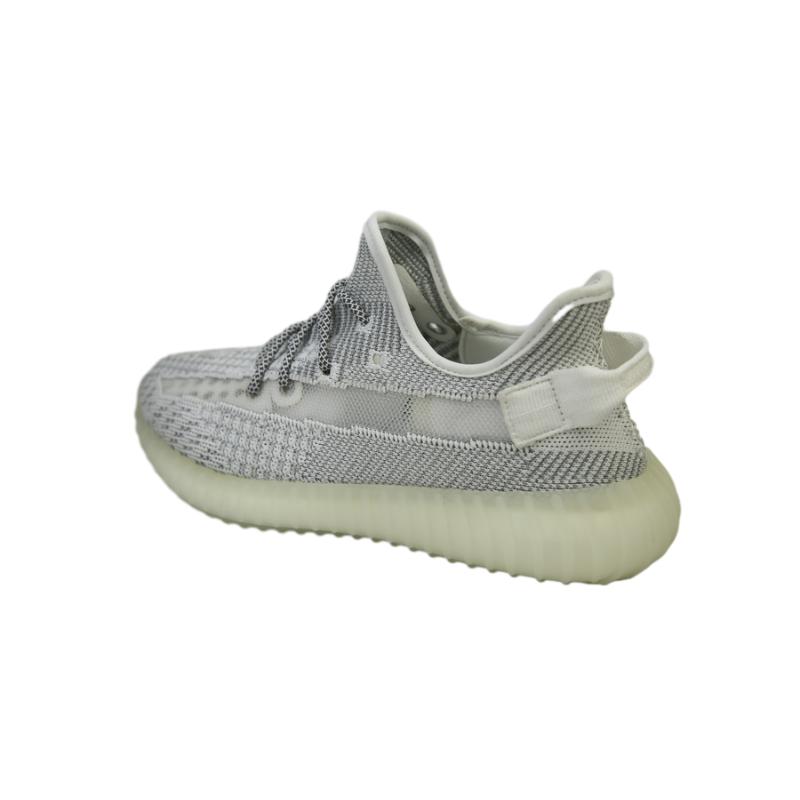

The slip-on design eliminates the need for laces, making these shoes easy to put on and take off, while the cushioned insole provides support and cushioning for your feet The slip-on design eliminates the need for laces, making these shoes easy to put on and take off, while the cushioned insole provides support and cushioning for your feet

The slip-on design eliminates the need for laces, making these shoes easy to put on and take off, while the cushioned insole provides support and cushioning for your feet The slip-on design eliminates the need for laces, making these shoes easy to put on and take off, while the cushioned insole provides support and cushioning for your feet Some boots even feature additional details such as buckles, bows, or textured soles, adding a touch of sophistication or playfulness Some boots even feature additional details such as buckles, bows, or textured soles, adding a touch of sophistication or playfulness

Some boots even feature additional details such as buckles, bows, or textured soles, adding a touch of sophistication or playfulness Some boots even feature additional details such as buckles, bows, or textured soles, adding a touch of sophistication or playfulness