First, let’s take a look at women’s hunting shoes made of Neoprene. Neoprene is a soft, elastic material that can provide excellent warmth and waterproofness, allowing the wearer to keep feet dry and warm in humid and cold environments. Hunting shoes made of this material usually adopt a high-top design, which can effectively protect the ankles, while also providing good grip and comfort, allowing female hunters to be more comfortable in outdoor activities. Moreover, hunting shoes made of Neoprene also have a long service life, making them a worthwhile investment in hunting shoes.

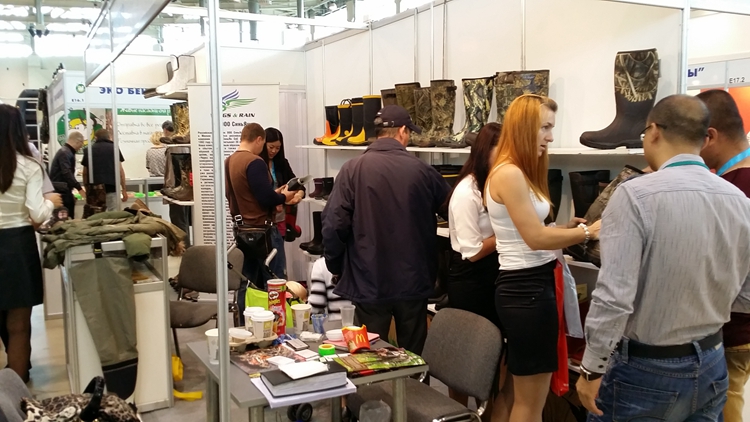

From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone

From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone insulated waterproof rain boots. You can even find styles that are lined with faux fur for extra warmth and comfort.

insulated waterproof rain boots. You can even find styles that are lined with faux fur for extra warmth and comfort.

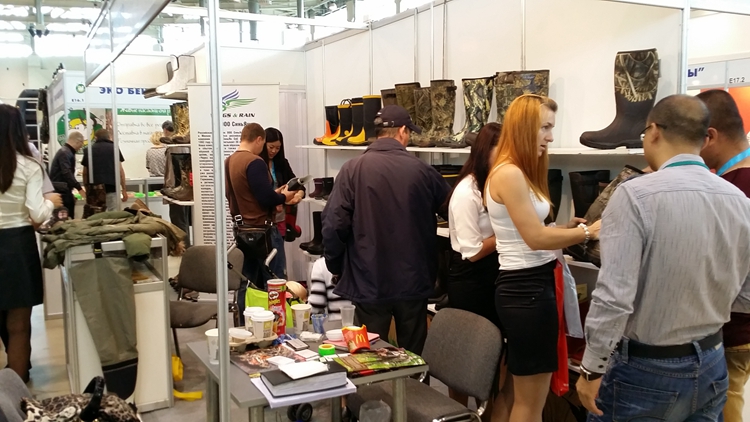

These costs are necessary for the operation of the manufacturing facilities and the marketing and distribution of the products These costs are necessary for the operation of the manufacturing facilities and the marketing and distribution of the products

These costs are necessary for the operation of the manufacturing facilities and the marketing and distribution of the products These costs are necessary for the operation of the manufacturing facilities and the marketing and distribution of the products