6. Quilting Foot Similar to the walking foot, a quilting foot often features a guide that helps in creating evenly spaced stitches. This foot is especially beneficial for free-motion quilting, as it allows for greater maneuverability.

To get the most out of your handheld leather stitcher, consider these tips

The single needle edge cutter machine also minimizes material waste. With precision cutting, manufacturers can optimize the use of fabric, ensuring that less material is discarded. This aspect of the machine is particularly beneficial in an era where sustainability and cost-effectiveness are critical considerations for textile companies.

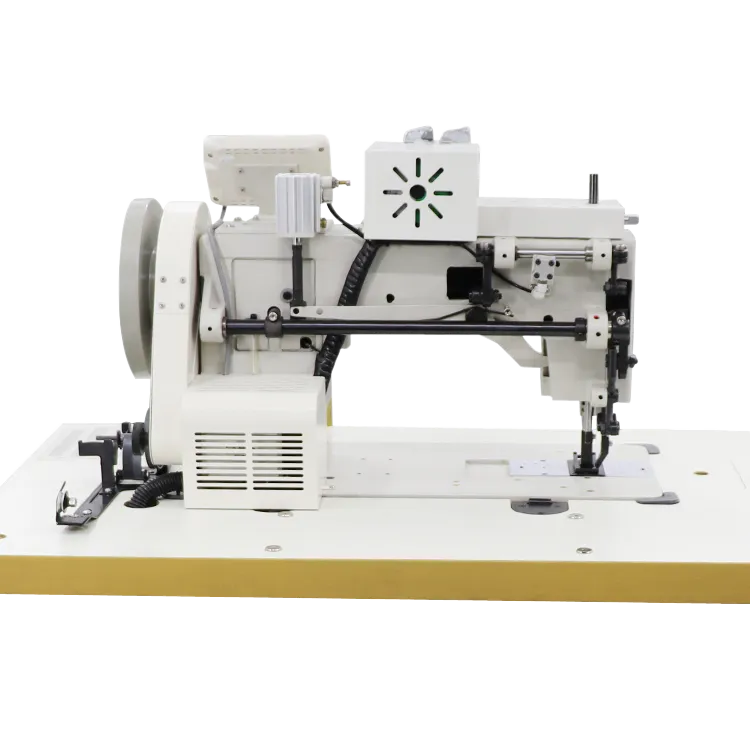

The hi-speed lockstitch machine operates using a simple yet effective mechanism. It employs a lockstitch formation, where a top thread and a bobbin thread interlock to create a strong, durable seam. This type of stitch is renowned for its ability to withstand stress and is exceptionally common in industrial applications. The machine’s hi-speed functionality allows it to sew at rates exceeding 5,000 stitches per minute, making it a crucial asset in high-volume production environments.

2. Stitch Variety A good heavy-duty sewing machine should offer a variety of stitch options to accommodate different sewing techniques and styles. Look for machines that feature straight stitches, zigzag stitches, and decorative stitching options, which allow for more creative freedom.

Industrial Sewing Machines: These tools are made for use in businesses. They are made to run for a long time, often several hours a day, and move a lot of stuff. They are usually found where many things are made, like clothing plants, upholstery shops, and other large-scale production settings.

A lock stitch is created by interlocking two threads—a top thread and a bobbin thread. The top thread is fed through the needle and forms a stitch on the front of the fabric. The bobbin thread, located in a lower compartment of the machine, loops up to meet the top thread, forming a secure stitch that is often used for a wide array of sewing applications. This type of stitch is characterized by its tightness and durability, making it suitable for sewing heavier materials such as denim and canvas, while also being gentle enough for lighter fabrics.

5. Variety of Stitch Options Many commercial upholstery machines come with multiple stitch options, including straight, zigzag, and decorative stitches. This versatility allows for creativity in design, making it easier to produce unique and appealing upholstery work.

6. Making Home Décor Items

inexpensive leather sewing machine. It also comes with a variety of accessories and features, such as a automatic needle threader and a built-in sewing light, making it a user-friendly option for those new to sewing.

In conclusion, the hi-speed lockstitch sewing machine is a cornerstone of modern textile production. Its ability to deliver high-speed, reliable stitching makes it an indispensable tool in various sectors, from fashion to upholstery. As technology continues to evolve, these machines are expected to incorporate even more innovative features, further enhancing their efficiency and capabilities.

Benefits of Using Double Needle Sewing Machines

use of double needle sewing machine

In today’s fast-paced industrial environment, efficient packaging is crucial for businesses aiming to maintain a competitive edge. Among the various elements of the packaging process, bag closing machinery plays a vital role in ensuring that products are securely sealed and ready for distribution. As industries continue to evolve, the demand for innovative bag closing solutions has surged, leading to the development of various types of machinery designed to cater to different needs.

The walking foot sewing machine is distinct from traditional sewing machines due to its specialized feeding system. Unlike standard machines that employ a presser foot and feed dogs for fabric movement, walking foot models utilize an additional walking foot mechanism that grips the fabric from the top and moves it in tandem with the feed dogs beneath. This coordinated movement ensures equal feeding of multiple layers of fabric, preventing slippage and misalignment—a common challenge when working with heavyweight materials like leather, canvas, and quilted fabrics. This capability makes the walking foot machine ideal for a variety of applications, from upholstery to outdoor gear and high-quality garment construction.

2. The main features of the heavy material sewing machine: the heavy material sewing machine adopts the upper and lower composite feeding and the cross-lifting mechanism of the presser foot to ensure that the upper and lower layers do not shift under any stitch length within the rated range, sewing slippery, viscous sewing material and special long products. The products are neat and the stitches are beautiful; the connecting rod thread take-up mechanism increases the spindle speed; the lower feeding shaft adopts sliding bearings, which reduces the noise and prolongs the service life.

4. Robust Construction Built to withstand the rigors of industrial use, 3-needle chain stitch machines are typically made from durable materials that ensure longevity and reliability.

When it comes to performance, the CB2500 does not disappoint. Its powerful motor enables smooth and consistent stitching at various speeds, catering to the preferences of different users. The machine’s ability to handle multiple layers of fabric without skipping stitches is particularly noteworthy, making it suitable for both lightweight and heavy materials.

Woven sack bags are made from interlaced strands of polypropylene or polyethylene, creating a sturdy, lightweight, and moisture-resistant packaging solution. These bags have become increasingly popular due to their ability to withstand severe conditions and their environmental friendliness, as they are recyclable. The versatility of woven sack bags makes them suitable for multiple applications, ranging from agricultural products to industrial goods.

On the higher end, professional-grade fully automatic sewing machines can cost anywhere from $1,500 to over $5,000. These models are equipped with a plethora of features designed for advanced sewers and professionals. They may include high-speed stitching, extensive embroidery designs, customizable settings, and superior build quality. Some high-end machines even offer computerized systems that can connect to design software for creating unique patterns and models.

Moreover, the use of these machines allows for greater design flexibility. Fashion designers can experiment with different stitching techniques and fabric combinations, knowing that the right equipment is available to bring their visions to life. This creative freedom is essential in an industry that thrives on innovation and new trends.

In the world of sewing and textiles, efficiency and versatility are paramount. For businesses and individuals tackling a variety of projects, commercial zig zag sewing machines offer an invaluable tool. These machines blend the traditional with the contemporary, providing sewists with the ability to perform a multitude of stitching techniques that cater to different fabric types and project needs.

1. Powerful Motor A heavy-duty sewing machine should come equipped with a powerful motor that can easily handle tough materials like denim, leather, and canvas. Look for machines that provide a higher stitch power (measured in watts or amps) as they will be better equipped to sew through multiple layers without jamming or breaking needles.

Further, the simplicity of operation allows novice users to learn the basics of sewing without being overwhelmed by advanced features. This can make manual machines an excellent choice for beginners or those interested in a more traditional sewing experience. Moreover, manual machines often provide greater control over sewing speed, which can be beneficial for intricate projects requiring precision.

Tips for Sewing with Heavy-Duty Thread

A walking foot sewing machine is characterized by its unique presser foot mechanism, which consists of multiple components that move in a synchronized manner to feed the fabric evenly through the machine. Unlike standard sewing machines, which rely solely on the feed dogs at the bottom, walking foot machines include a top feed mechanism. This allows the top layer of fabric—such as heavy leather—to be moved in perfect harmony with the lower layer, preventing slipping and uneven stitching.