The rubber component of the boots is another aspect that cannot be overlooked. Rubber is inherently waterproof, making these boots suitable for various weather conditions. Whether it's a light spring drizzle or a downpour, the feet stay protected and dry. Moreover, rubber is known for its robustness and grip, which means these boots can handle both urban sidewalks and more rugged terrains with equal aplomb Moreover, rubber is known for its robustness and grip, which means these boots can handle both urban sidewalks and more rugged terrains with equal aplomb Moreover, rubber is known for its robustness and grip, which means these boots can handle both urban sidewalks and more rugged terrains with equal aplomb Moreover, rubber is known for its robustness and grip, which means these boots can handle both urban sidewalks and more rugged terrains with equal aplomb

Moreover, rubber is known for its robustness and grip, which means these boots can handle both urban sidewalks and more rugged terrains with equal aplomb Moreover, rubber is known for its robustness and grip, which means these boots can handle both urban sidewalks and more rugged terrains with equal aplomb men's slip on rubber ankle boots.

men's slip on rubber ankle boots.

Designers have embraced this trend, introducing a myriad of colors, patterns, and textures, transforming the traditional gumboot into a fashionable accessory that reflects individuality Designers have embraced this trend, introducing a myriad of colors, patterns, and textures, transforming the traditional gumboot into a fashionable accessory that reflects individuality

Designers have embraced this trend, introducing a myriad of colors, patterns, and textures, transforming the traditional gumboot into a fashionable accessory that reflects individuality Designers have embraced this trend, introducing a myriad of colors, patterns, and textures, transforming the traditional gumboot into a fashionable accessory that reflects individuality

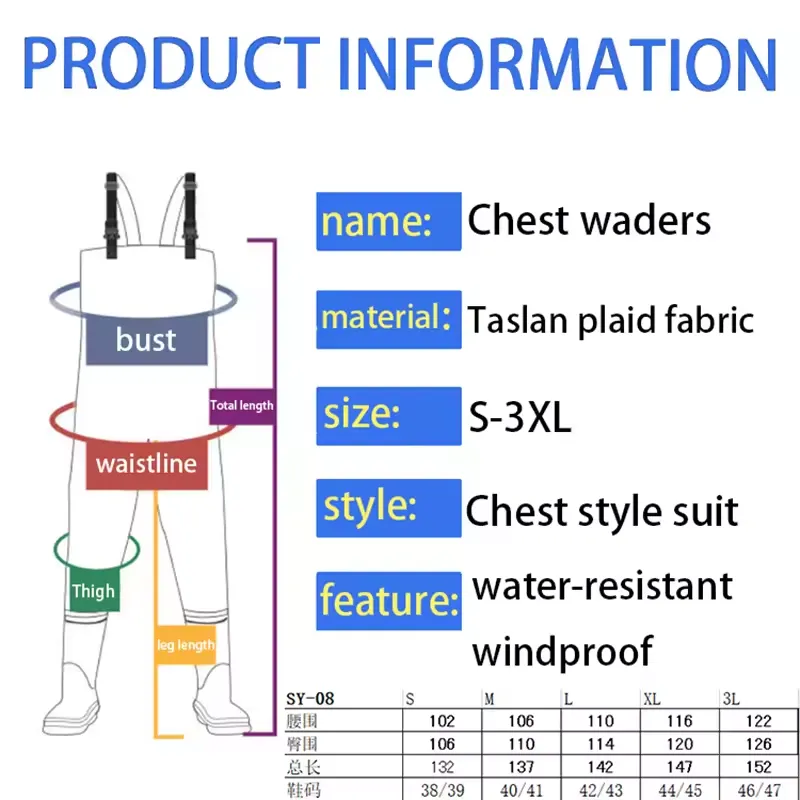

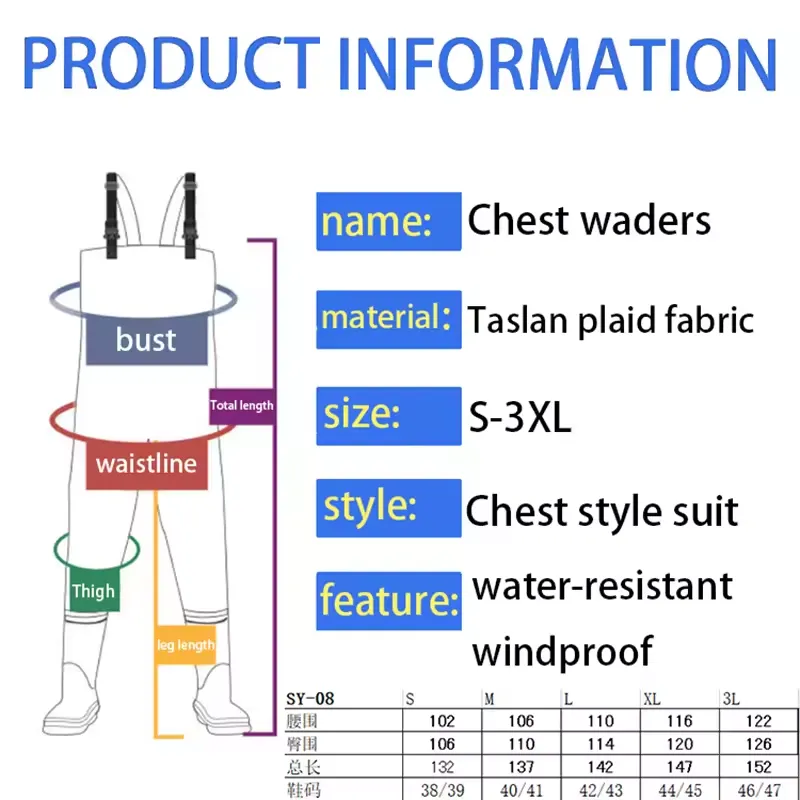

Some models come with integrated boots, while others require separate booties or allow you to wear your own footwear Some models come with integrated boots, while others require separate booties or allow you to wear your own footwear

Some models come with integrated boots, while others require separate booties or allow you to wear your own footwear Some models come with integrated boots, while others require separate booties or allow you to wear your own footwear They are designed to adapt to diverse environments, with enhanced insulation that keeps the wearer warm and dry in cold, damp conditions They are designed to adapt to diverse environments, with enhanced insulation that keeps the wearer warm and dry in cold, damp conditions

They are designed to adapt to diverse environments, with enhanced insulation that keeps the wearer warm and dry in cold, damp conditions They are designed to adapt to diverse environments, with enhanced insulation that keeps the wearer warm and dry in cold, damp conditions