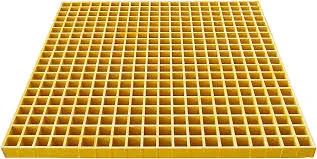

Pultruded fiberglass grating is made using premium grade isophthalic polyester, vinyl ester or phenolic resin systems with a synthetic surfacing veil, making it corrosion resistant, lightweight, and durable. Pultruded fiberglass has a grit surface for safety, and a greater strength to weight ration than molded fiberglass grating. A 35% / 65% resin to glass ratio provides greater strength and less corrosion resistance than molded fiberglass. This product is better suited for longer life spans. For more on pultruded fiberglass grating, click here.

thigh waders. For photographers, they facilitate access to unique vantage points, capturing stunning images from the heart of nature. In conservation, they protect workers from harsh conditions while enabling them to perform tasks in flooded areas.

thigh waders. For photographers, they facilitate access to unique vantage points, capturing stunning images from the heart of nature. In conservation, they protect workers from harsh conditions while enabling them to perform tasks in flooded areas. This is particularly crucial during rough seas or when maneuvering on a heaving boat This is particularly crucial during rough seas or when maneuvering on a heaving boat

This is particularly crucial during rough seas or when maneuvering on a heaving boat This is particularly crucial during rough seas or when maneuvering on a heaving boat

They've transcended their utilitarian roots and found a place in high fashion, gracing runways and celebrity red carpets They've transcended their utilitarian roots and found a place in high fashion, gracing runways and celebrity red carpets

They've transcended their utilitarian roots and found a place in high fashion, gracing runways and celebrity red carpets They've transcended their utilitarian roots and found a place in high fashion, gracing runways and celebrity red carpets