heat resistant electrical tape.

Versatility and Style

boots manufacturers. Leather, canvas, and synthetic materials are among the most commonly used materials, each with its own unique properties and benefits. Once the materials have been selected, they are cut and sewn together to create the boot's upper. The outsole is then attached, followed by the addition of any additional features such as zippers, laces, or buckles. Finally, the boots are inspected for quality and shipped to retailers or directly to consumers.

boots manufacturers. Leather, canvas, and synthetic materials are among the most commonly used materials, each with its own unique properties and benefits. Once the materials have been selected, they are cut and sewn together to create the boot's upper. The outsole is then attached, followed by the addition of any additional features such as zippers, laces, or buckles. Finally, the boots are inspected for quality and shipped to retailers or directly to consumers.

black boots rubber heel. Designers have continually reimagined this footwear silhouette, infusing it with contemporary twists or maintaining its original, minimalist charm. From chunky combat boots to sleek ankle boots, the variations are endless, catering to diverse personal styles.

black boots rubber heel. Designers have continually reimagined this footwear silhouette, infusing it with contemporary twists or maintaining its original, minimalist charm. From chunky combat boots to sleek ankle boots, the variations are endless, catering to diverse personal styles.

Moreover, these boots often feature durable, waterproof construction, ensuring feet stay dry amidst the heaviest downpours Moreover, these boots often feature durable, waterproof construction, ensuring feet stay dry amidst the heaviest downpours

Moreover, these boots often feature durable, waterproof construction, ensuring feet stay dry amidst the heaviest downpours Moreover, these boots often feature durable, waterproof construction, ensuring feet stay dry amidst the heaviest downpours low cut mens rain boots.

low cut mens rain boots.

Neoprene-lined wellington boots are the perfect blend of style and functionality for those who enjoy outdoor activities in all types of weather. These boots are not only fashionable but also incredibly practical, offering protection and comfort for any adventure. With their unique design and material, neoprene-lined wellington boots have become a popular choice among outdoor enthusiasts.

If you're a woman who loves spending time outdoors and exploring the wilderness, then you know the importance of having the right gear. One essential item for any outdoor adventure is a pair of snake-proof boots. These specialized boots are designed to protect your feet from venomous snakes, giving you peace of mind as you navigate through snake-inhabited areas.

When it comes to outdoor activities such as hunting and fishing, having the right footwear is essential for comfort, protection, and performance. Let's explore the top footwear options for outdoor enthusiasts, including outdoor hunting boots, wet wading fishing shoes, and boots for wet wading.

The result is a wader that withstands the rigors of fishing while keeping the wearer dry and content The result is a wader that withstands the rigors of fishing while keeping the wearer dry and content

The result is a wader that withstands the rigors of fishing while keeping the wearer dry and content The result is a wader that withstands the rigors of fishing while keeping the wearer dry and content big and tall waders.

big and tall waders.

Fishing can be a rough-and-tumble activity, so durability is a key feature of any chest waders. Look for reinforced seams and materials that can withstand abrasions and punctures. After a day on the water, proper maintenance is crucial to extending the life of your waders. Rinse them with fresh water to remove any contaminants, and allow them to dry completely before storing them away to prevent mold and mildew.

Fishing boots with waterproof features are essential for anglers seeking reliable protection and comfort during fishing expeditions. These boots are designed to offer waterproofing, traction, and support, ensuring that anglers can navigate through wet and challenging environments with confidence. The waterproof construction provides anglers with the necessary features for a successful and comfortable fishing experience.

They can easily be paired with jeans for a casual outing, dressed up with a skirt and tights for a more formal occasion, or worn with shorts for a fun, adventurous look They can easily be paired with jeans for a casual outing, dressed up with a skirt and tights for a more formal occasion, or worn with shorts for a fun, adventurous look

They can easily be paired with jeans for a casual outing, dressed up with a skirt and tights for a more formal occasion, or worn with shorts for a fun, adventurous look They can easily be paired with jeans for a casual outing, dressed up with a skirt and tights for a more formal occasion, or worn with shorts for a fun, adventurous look womens wide calf rubber boots.

womens wide calf rubber boots.

Furthermore, the tape’s easy-to-use nature adds to its appeal. It can be torn by hand, which eliminates the need for extra tools such as scissors or knife cutting. Whether someone is working in a workshop, on a construction site, or simply tackling a DIY project at home, PVC black tape can be easily applied and removed as needed. Its peel-and-stick functionality allows for quick application, which can significantly enhance productivity in busy work environments.

It requires an understanding of the warehouse's workflow, storage systems, and safety protocols It requires an understanding of the warehouse's workflow, storage systems, and safety protocols

It requires an understanding of the warehouse's workflow, storage systems, and safety protocols It requires an understanding of the warehouse's workflow, storage systems, and safety protocols warehouse floor tape. Installers must ensure that the tape is applied evenly and securely to the floor to withstand the heavy foot and vehicle traffic without peeling or curling at the edges. The choice of material for the tape is also critical; it must be durable enough to endure the constant wear and tear yet flexible enough not to crack under pressure or temperature changes.

warehouse floor tape. Installers must ensure that the tape is applied evenly and securely to the floor to withstand the heavy foot and vehicle traffic without peeling or curling at the edges. The choice of material for the tape is also critical; it must be durable enough to endure the constant wear and tear yet flexible enough not to crack under pressure or temperature changes.Q: Can I use 3M Rubber Electrical Tapes for all types of wires?

It is also known as insulating tape or insulation tape. Electrical tape is made from a variety of materials, including vinyl, rubber, cloth, and paper.

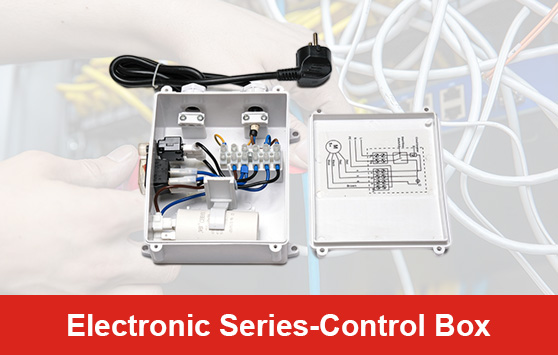

Understanding Busbar Insulation