First and foremost, rubber boots are renowned for their waterproof properties. Made primarily from natural or synthetic rubber, they effectively keep water out, ensuring feet remain dry in wet environments. Whether you're trudging through rain-soaked streets, wading through puddles, or working in flooded areas, rubber boots provide unparalleled protection against saturation. They are a staple for farmers, construction workers, fishermen, and even for those engaged in outdoor recreational activities like gardening or hiking.

Comfort The cushioned insoles and moisture-wicking materials used in rubber muck boots provide all-day comfort, even in the most challenging environments Comfort The cushioned insoles and moisture-wicking materials used in rubber muck boots provide all-day comfort, even in the most challenging environments

Comfort The cushioned insoles and moisture-wicking materials used in rubber muck boots provide all-day comfort, even in the most challenging environments Comfort The cushioned insoles and moisture-wicking materials used in rubber muck boots provide all-day comfort, even in the most challenging environments

This is particularly important for those who work outdoors or in refrigerated environments This is particularly important for those who work outdoors or in refrigerated environments

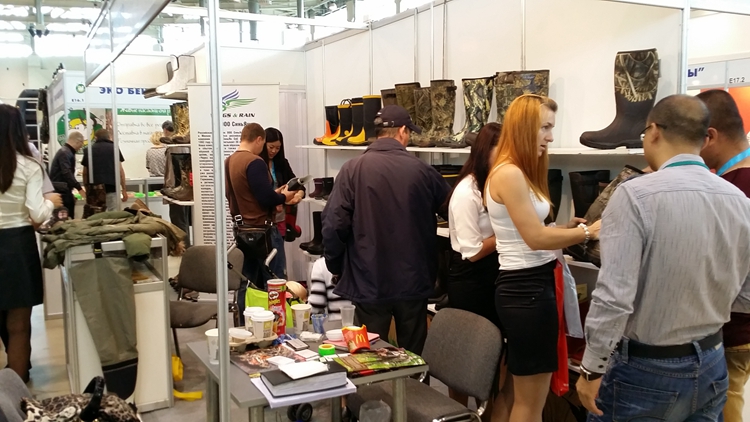

This is particularly important for those who work outdoors or in refrigerated environments This is particularly important for those who work outdoors or in refrigerated environments From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone

From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone From classic black to vibrant patterns, there is a pair of insulated waterproof rain boots for everyone